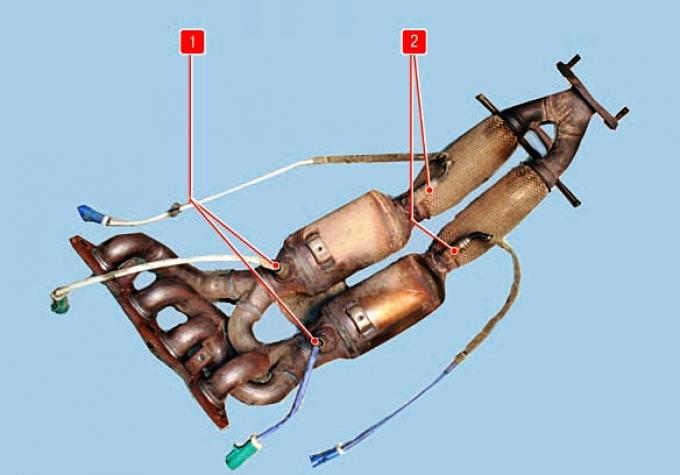

Pic. 5.61. 1.6 l Duratec Ti-VCT engine collector: 1 – oxygen concentration control sensors; 2 – diagnostic oxygen concentration sensors.

Exhaust gases are removed from the engine through the collector (exhaust manifold combined with one or two converters) …

…additional…

...and two main mufflers.

On vehicles with a 1.6 liter Duratec Ti-VCT engine, the collector includes two exhaust gas converters, on vehicles with 2.0 and 2.3 liter Duratec-HE engines - one converter.

The 1.6L Duratec Ti-VCT engine has two control valves mounted on its manifold (major) sensor 1 (pic. 5.61) oxygen concentration and two diagnostic sensors 2.

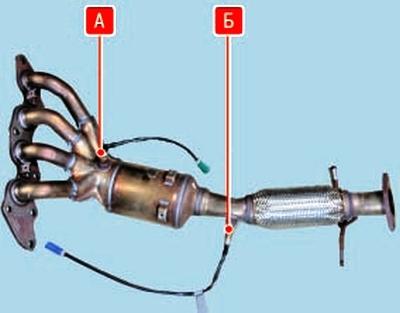

On the collector of 2.0 and 2.3 l Duratec-HE engines, one control A and one diagnostic B oxygen concentration sensors are installed.

A metal-reinforced gasket is used to seal the connection between the flanges of the cylinder head and the collector.

The downpipe of the additional silencer is connected to the collector, and its exhaust pipe is connected to the main silencers. The connections of the intake and intermediate pipes with an additional silencer, as well as the intermediate and exhaust pipes with the main silencers, are welded and therefore non-separable. The flange connection of the intake pipe of the additional muffler and the collector is sealed with a metal-reinforced gasket. Thus, all elements of the exhaust system, located on the base of the body, are made in one piece and cannot be dismantled separately without the use of a metal-cutting tool. However, spare parts are supplied with individual elements of the system, which, when mounted on a vehicle, are connected by welding or special couplings.

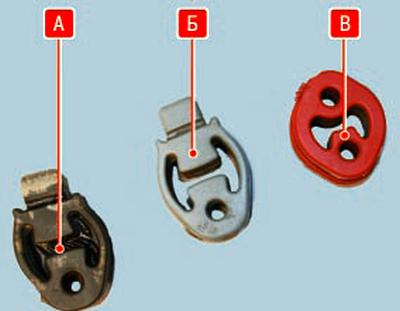

The elements of the system are suspended from the body on five rubber cushions. Moreover, pillow A of the rear suspension of the exhaust pipe, pillow B of the suspension of the front part of the main silencer and three pillows C of the suspension of the collector and the rear of the main silencer differ in shape.

To protect the engine and body base from heating by the elements of the system, thermal screens made of heat-resistant non-woven material are installed above the collector, additional and main mufflers.

In addition, an additional steel thermal screen is installed above the collector.

The exhaust system does not require special maintenance. It is enough to periodically check the reliability of the tightening of the threaded connections and the integrity of the suspension pads. In case of damage to the elements of the system, through corrosion or burnout, they are replaced as an assembly, since the mufflers, together with the pipes, are non-separable units.

GOOD ADVICE: Periodically check the exhaust system. If there is an increased noise level from the exhaust system, check its tightness. To do this, start the engine and inspect the entire system. Run your hand over potential leaks without touching the components, and you will immediately feel the release of gases. If necessary, replace rusted and burnt parts.

If it is impossible to replace the defective unit with a new one, you can temporarily restore its performance by applying a metal patch to the damaged area and securing it with clamps or wire. It is recommended to place a sheet of asbestos under the patch.

In addition, auto parts stores sell special kits for rebuilding exhaust system components, with which you can temporarily repair damage to the system in order to get to a car service or garage.

WARNING: Before repairing the exhaust system, allow it to cool down as it becomes very hot when the engine is running.

Exhaust gases are poisonous, their poisoning occurs imperceptibly, so be sure to open the gate before starting the engine in the garage!

Visitor comments