USEFUL ADVICE: If the clutch fails, we recommend replacing all its elements at the same time (driven and driven discs, as well as clutch release bearing), since the work of replacing the clutch is laborious, and the life of intact clutch elements has already been reduced and, if they are installed again, it may be necessary to replace the clutch again after a relatively short run.

You will need: key "10" (more comfortable socket head), mounting blade, mandrel for centering the driven disk.

You can use a commercially available front wheel drive mandrel VAZ cars.

1. Remove the gearbox (see Removing and installing transmission).

2. If you install the old pressure plate, mark in any way (e.g. paint) the relative position of the disc housing and the flywheel to set the pressure plate in its original position (to maintain balance).

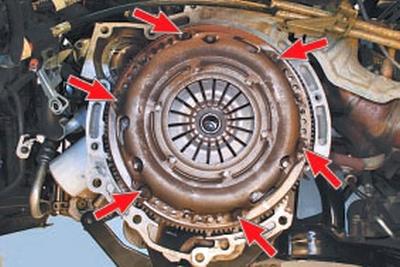

3. Holding the flywheel with a spudger (or a large screwdriver) from turning, unscrew the six bolts securing the clutch pressure plate housing to the flywheel. Loosen the bolts evenly: each bolt one turn, moving from bolt to bolt in diameter.

NOTE: This is the location of the bolts securing the clutch cover to the engine flywheel.

4. Remove the clutch pressure and driven discs from the flywheel while holding the driven disc.

5. Examine a conducted disk of coupling.

Cracks on the details of the driven disk are not allowed.

6. Check the degree of wear of the friction linings. If the rivet heads are sunk by less than 0.2 mm, the surface of the friction linings is oily, or the rivet connections are loose, then the driven disk must be replaced. Squeeze the friction linings with your hands. If the total disc thickness when compressed is less than 5.5 mm for gasoline engines and less than 5.0 mm for diesel engines, also replace the disc.

NOTE: If the driven plate linings are oily, check the condition of the transmission input shaft oil seal. It may need to be replaced.

7. Check up reliability of fixing in nests of a nave of a conducted disk of damper springs, trying to move them in nests of a nave a hand. If the springs move easily in their seats or are broken, replace the disc.

8. Check up beating of a conducted disk if its warping is found out at visual inspection. If the runout is more than 0.5 mm, replace the disc.

9. Inspect the friction surfaces of the flywheel and pressure plate, paying attention to the absence of deep scratches, scuffs, nicks, obvious signs of wear and overheating.

Replace defective units.

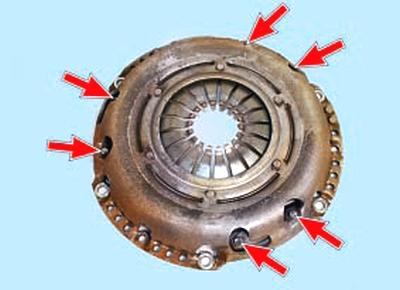

10. If the rivet joints of the casing and pressure plate parts are loose, replace the pressure plate assembly.

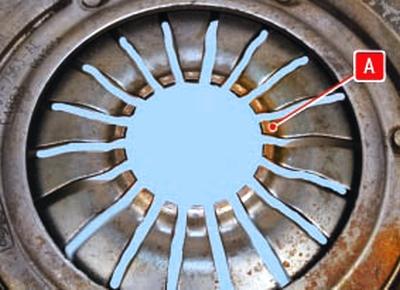

11. Visually evaluate the condition of the pressure plate diaphragm spring. The presence of cracks on the diaphragm spring is not allowed. Places A of contact between the petals of the spring and the clutch release bearing must be in the same plane and not have obvious signs of wear (wear should not exceed 0.8 mm).

Otherwise, replace the pressure plate assembly.

12. Inspect the connecting links of the casing and disc. If the links are deformed or broken, replace the pressure plate assembly.

13. Visually evaluate the condition of the pressure spring support rings from the outer..

14.... and the inside of the spring. Rings must be free of cracks and signs of wear.

Otherwise, replace the pressure plate assembly.

15. Before installing the clutch, check the ease of movement of the driven disk along the splines of the input shaft of the gearbox.

If necessary, remove the causes of seizing or replace defective parts.

16. Apply high-melting grease to the splines of the driven disc hub.

17. When mounting the clutch, first install the driven disk using a mandrel..

NOTE: Install the driven plate so that the inscription "GEARBOX-SIDE" is directed towards the gearbox (the protruding part of the disc hub must be directed towards the diaphragm spring of the clutch housing).

18.... and then on the three centering pins the casing of the pressure plate and screw in the bolts securing the casing to the flywheel.

19. Screw the bolts evenly, one turn each, alternately moving from bolt to bolt in diameter. The tightening torque of the bolts is specified in appendix 1.

20. Remove the mandrel and install the gearbox.

21. Check clutch operation (refer to Checking Clutch Release Pedal Travel).

Visitor comments