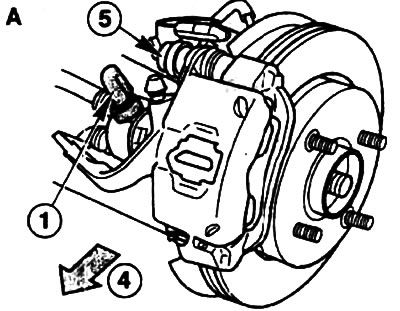

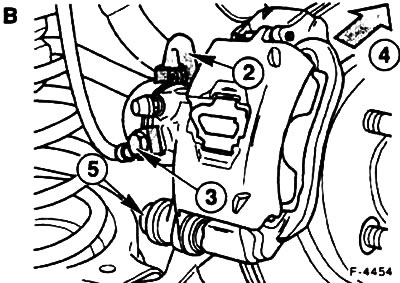

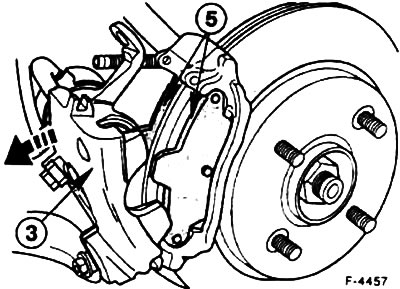

Due to the fact that the cars have different rear suspension and different trunnion designs, on the Limousine -A- the brake caliper is located in front. and on a Turnier car -B- behind the axle trunnion. Arrows -4- in both pictures show the direction of movement. In both cases, the brake calipers are attached in the same way, only the fastening parts are turned. 1 - Parking brake cable lever, 2 - Parking brake cable lever, 3 - Brake hose hollow bolt.

Withdrawal

Mark the position of the wheels on the hub with paint in order to install them in their original place during assembly. Loosen the wheel nuts with the vehicle lowered. Raise the rear of the car and remove the rear wheels.

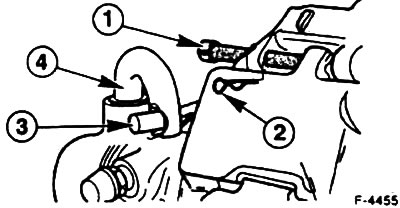

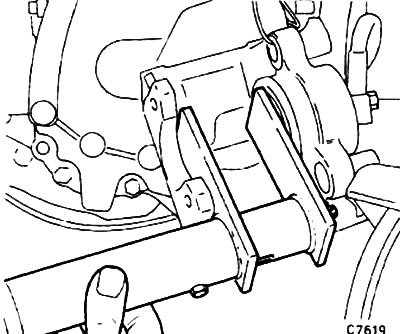

Remove cotter pin -3- from pin -1- with a small screwdriver.

Attention! The picture shows a Turnier car. On the Limousine, the pin is on the bottom pin.

If necessary, disconnect the brake hose from the holder to avoid tension.

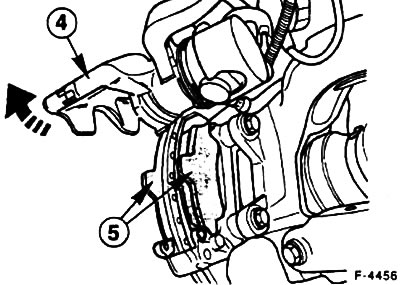

Limousine: Turn the brake caliper -4- up from the brake caliper.

Turnier: Rotate caliper -3- down from brake caliper.

Firmly compress the brake hose with a suitable hose clamp and loosen the hose connection on the brake caliper.

Attention! It is important that a suitable hose clamp is used that will not damage the hose.

Remove the pads -5- from the brake caliper.

Attention! If you intend to install the same pads back, then mark their location when removing them. Changing pads in places is unacceptable, as this will lead to uneven braking. Use only genuine FORD pads or those approved by the FORD factory. Replace all disc brake pads at the same time, even if only one pad has reached its wear limit. Different wear of the linings is not a reason for complaints. If the difference in the outer lining is more than 2 mm, then check the ease of movement of the piston, as well as the brake callipers in the guides, replace if necessary (service station operation).

Installation

Attention! Do not press the brake pedal with the brake pads removed, otherwise the piston will be squeezed out of the housing. If the piston is inadvertently squeezed out of the body, then remove the bracket and assemble it in a specialized workshop.

Clean the guide surfaces and pad seats in the body shaft with a suitable soft metal brush and clean with a vacuum cleaner or a cloth dampened with alcohol. Do not use solvents containing mineral oils or sharp-edged tools for cleaning.

Before installing the pads, check the surface of the brake disc with your finger for the absence of scratches. Measure the brake disc thickness see point 15.3.

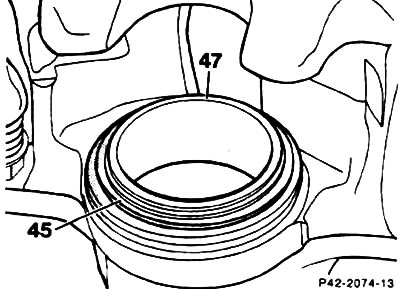

Check dust cap -45- for marks. Replace a damaged dust boot without delay, as infiltrating dirt will quickly cause the brake caliper to leak. In this case, it must be removed and disassembled (service station operation).

Push in the piston with the tool. You can also use a hardwood block for this (hammer handle), at the same time make sure that the piston does not warp, try not to damage the surface of the piston and anther.

Attention! When the piston is pressed in, the brake fluid from the brake cylinder is squeezed out into the expansion tank. Monitor the fluid level in the tank, if necessary, remove the fluid from the tank with a rubber bulb.

To draw off the brake fluid, use a bleed vessel or a plastic vessel that will only be used for brake fluid. Do not use drinking utensils! Brake fluid is poisonous, never suck the fluid through the hose with your mouth. Use a rubber bulb. After replacing the brake pads, do not fill fluid above the mark "MAX" on the reservoir, as brake fluid expands when heated. Leaking brake fluid gets on the master cylinder, destroys the paintwork and contributes to the formation of rust.

Attention! If the brake pads wear quickly, check the ease of movement of the brake cylinder. To do this, insert a wooden block into the brake caliper and slowly depress the brake pedal (assistant). The piston should move easily back and forth. When checking, the second bracket with pads must be installed. Make sure that the piston is not squeezed out of the cylinder completely. If the piston is hard to move, replace the bracket (service station operation).

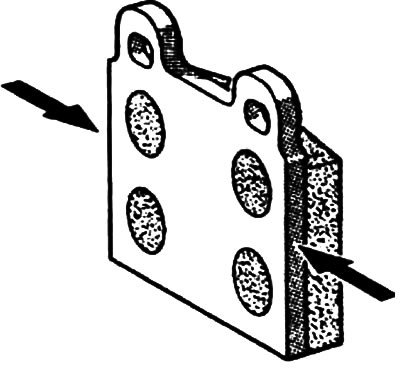

The following operation is optional, but desirable: In order to eliminate the squeaking of disc brakes, you can lubricate the back surface of the pad and the sides of the plate -arrows- with a thin layer of grease (e.g. Plastilube, Tunap VC 582/S, Cheevron SRJ/2, Liqui Moly LM-36 or LM-508-ASC). The paste must never get on the brake discs and linings. Otherwise, wash off the grease immediately and wipe the pads or disc with alcohol.

Install new pads in the brake caliper.

Lower the brake caliper (Limousine) or turn up (Turnier) and press on it.

Install the fastening pin and lock it with a cotter pin.

Tighten the brake hose, remove the hose clamp.

Bleed the air from the brake system, see clause 15.12.

Install the rear wheels so that the marks made earlier match. Apply a light coat of grease to the centering surface on the wheel hub before installing the wheels. Screw on the wheel nuts. Lower the vehicle and tighten the nuts crosswise to 100 Nm.

Attention! Depress the brake pedal several times until you feel good pedal resistance. Thus, the pads will press against the brake disc and take their working position.

Check the fluid level in the expansion tank, top up if necessary "MAX".

Brake the vehicle several times by gently depressing the brake pedal from 80 km/h to 40 km/h.

Attention! During the first 200 km, avoid unnecessary emergency braking.

Note! Brake linings are disposed of as special waste.

Visitor comments