In order to compensate for various expansions of the timing mechanism due to heat, there must be a certain distance between the cams of the camshaft and the corresponding poppets. This distance for the valves changes over time due to tighter lapping of the valves and wear of the gas distribution mechanism.

If the distance is too small, the valve timing changes, the result is poor compression, the engine power decreases, the engine runs restlessly. In extreme cases, the valves may be deformed, the valves themselves or the valve seats may be burned.

If the distance is too far, strong mechanical noises occur, the valve timing changes, the valves in the engine open for a very short period of time, poor filling of the cylinder, the engine power decreases, the engine runs unevenly.

Valve clearances should be checked every 40,000 km as part of maintenance, the same must be done after repair if noise occurs in the gas distribution mechanism: if necessary, adjust valve clearances.

Valve clearances are checked and adjusted on a cold engine (ambient temperature).

Examination

Remove from a head of the block of cylinders hoses of ventilation of the engine, before release fixing collars.

Remove the cylinder head cover by unscrewing the three bolts.

Unscrew the oil deflector, it is attached under the cylinder head cover with four nuts.

Turn the crankshaft until the pair of cams of the adjustable cylinder are equally facing up. There are three ways to turn the crankshaft:

- 1) shift the transmission to the neutral position, apply the parking brake and slip the removable head of the ratchet wrench over the central bolt of the belt pulley;

- 2) engage fifth gear, release the parking brake and move the car slightly;

- 3) Raise the car from the right front so that the wheel can turn freely. Engage fifth gear and rotate the right front wheel by hand.

Slide a flat gauge between the cam and poppet and measure the valve clearance. Target values for valve clearances (cold engine):

- Inlet valves: 0.35±0.05 mm;

- Exhaust valves: 0.50±0.05 mm;

Attention! The location of the valves on the side of the toothed belt for all cylinders: 1st - inlet, 2nd - exhaust valves.

A flat template of the appropriate thickness must pass between the cam and the poppet without problems. Record the measured result.

Turn the crankshaft another 1/2 turn and check the valve clearance in the next cylinder, i.e. in the cylinder in which the ignition takes place. Ignition sequence: 1-3-4-2.

Adjustment

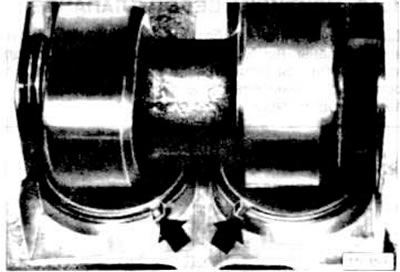

To adjust the valve clearances, replace the existing shim with a new, thicker shim.

Attention! With an increase in engine service life, as a rule, valve clearances are reduced due to lapping and running in of valves, i.e. this means that the existing washer must be replaced with a thinner one.

Example:

- Control tolerances: 0.030-0.40mm (0.35±0.05mm)

- Measured value: 0.25 mm

- Gap: 0.05mm too small

If the measurement results are within the tolerance range, then the shim does not need to be changed. If the measurement result is out of range, then when adjusting, you should strive to obtain a minimum value, here 0.35 mm.

Existing shim: 3.85 mm.

Required shim: 3.75 mm (to get the average).

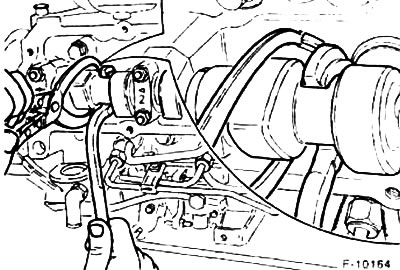

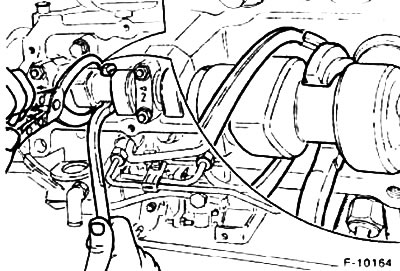

Adjust valve clearances. For this purpose, Ford workshops use a special tool 21-106 and 21-107 or HAZET-3474 and 3499. Valve adjustment is impossible without the mentioned tool.

Attention! When adjusting valve clearances, the piston must not be at TDC, otherwise the valves and/or pistons may be damaged. Rotate the crankshaft 1/4 turn.

Before installing the locking device in the lower position, turn the poppets so that when pressed down, the tongs can engage in the recesses.

The poppet pusher together with the locking device in the lower position, press down and remove the adjusting washer. Finally, lay the new washer so that the inscription faces down.

Remove the locking device in the lower position and rotate the camshaft.

Adjust the valves of other cylinders in the same way.

Install the oil deflector in the cylinder head, tighten the four fixing nuts with a torque of 20 Nm.

Screw on the cylinder head cover with a new seal. Lightly tighten the three bolts to 5 Nm or you will crush the seal.

Connect the engine ventilation hoses to the cylinder head cover, secure them with clamps.

Visitor comments