Find out if there are cracks on the suspension parts or traces of rubbing against road obstacles or the body, deformation of the levers, stabilizer bar, rear body parts at the attachment points of suspension units and parts.

Check the condition of rubber-metal hinges, rubber cushions, condition (draft) suspension springs.

Rubber-metal hinges and rubber pads must be replaced in case of ruptures and one-sided buckling of rubber, as well as when cutting their end surfaces.

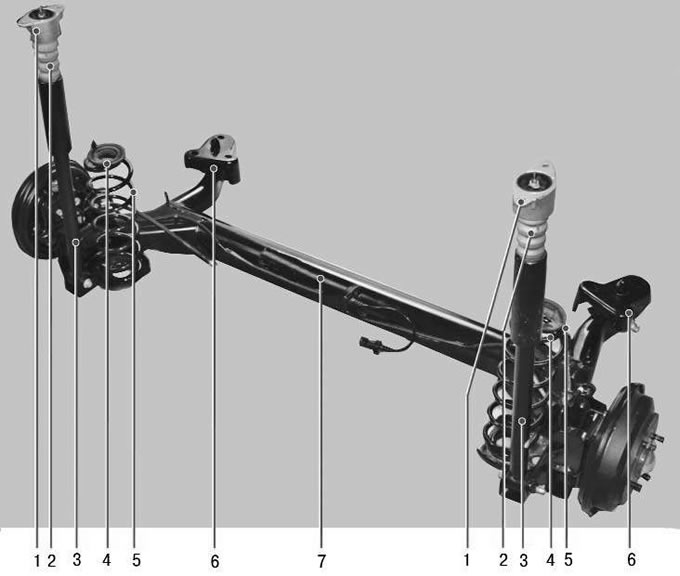

The arrangement of elements of a back suspension bracket on the car is shown on fig. 4.3.

Pic. 4.3. The location of the rear suspension elements on the car: 1 – a support of a shock-absorber of a back suspension bracket; 2 – compression buffer; 3 - rear suspension shock absorber; 4 – laying of a spring of a back suspension bracket; 5 - rear suspension spring; 6 - silent block; 7 - rear suspension beam

On rubber-metal hinges are not allowed:

- signs of aging, cracks;

- one-sided buckling of the rubber array.

Replace defective parts.

Check for mechanical damage (deformations, cracks, etc.) suspension elements.

1. Inspect the rubber bushings of the lower shock mount and shock absorbers. Shock absorbers must not drip fluid and «sweating».

2. Check the rubber joints (silent blocks) rear suspension mounts.

3. Check the springs.

Note. Pay attention to the exhaust system. Extraneous knocks published by her are often mistaken for a knock in the rear suspension. The use of non-standard parts or the breakage of the muffler suspension elements can cause a strong knock, especially during regassing. To check, stop the engine, carefully inspect the exhaust system, check the reliability of the mounting and suspension of the muffler. Grasping the end of the exhaust pipe, shake the muffler up and down and from side to side - there should be no knocks.

Visitor comments