- traces of oil on any surface of the belt;

- signs of wear of the toothed surface, cracks, undercuts, folds and delamination of the fabric from the rubber;

- cracks, folds, depressions or bulges on the outer surface of the belt;

- fraying or delamination on the end surfaces of the belt.

Attention! A belt with traces of engine oil on any of its surfaces must be replaced, as oil quickly destroys rubber. Cause of oil on the belt (usually this is a violation of the tightness of the seals of the crankshaft and camshaft) must be eliminated immediately.

Note. Carry out work on a viewing ditch, overpass or, if possible, on a lift.

You will need: special tools for locking the camshafts and crankshafts and the timing belt tensioner pulley, a socket wrench «on 10», box wrenches or sockets «for 8», «at 13», keys «at 18» and TORX E8.

1. Raise the front of the vehicle and place it on a secure stand. Remove the right front wheel (see «Wheel replacement»).

2. Remove the right front fender liner (see «Removal and installation of wheel mudguards and fender liner»).

3. Remove the engine mudguard (see «Removal and installation of a mudguard of the engine»).

4. Remove the power steering pump drive belt by cutting it with a knife.

5. Remove the accessory drive belt by cutting it with a knife.

Note. According to the manufacturer's recommendations, the belts for the drives of auxiliary units and the power steering pump should be cut with a knife for removal, after which they become unusable. This is due to the fact that both belts, even after being removed without damage, cannot be reused, since they are designed only for one-time stretching when put on pulleys (belt tension adjustment is not provided). In addition, the replacement of belts is regulated after a certain mileage or service life, therefore, when replacing the accessory drive belt, the power steering pump drive belt should also be replaced at the same time.

6. Turn out a bolt of fastening of a broad tank …

7.... prying off the retainer with a screwdriver, remove the expansion tank from the bracket and take it aside.

8. Remove the cylinder head cover (see «Replacing the cylinder head cover gasket»).

9. Unscrew the plug located in the front of the cylinder block on the right, and screw the fixing rod into the opened hole until it stops against the crankshaft. Carefully turn the crankshaft by the bolt securing its pulley until the shaft stops with the fixing rod.

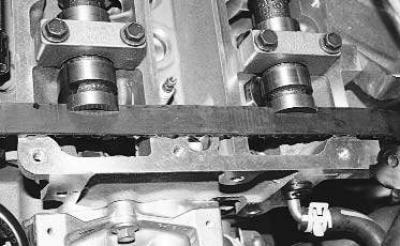

10. Secure the camshafts from turning by fitting the locking plate into the grooves at the rear of the camshafts.

11. Turn out a bolt of a pulley of a cranked shaft.

Note. The crankshaft pulley bolt is tightened with a large torque. In order to fix the crankshaft from turning, turn on V gear, press and hold the brake pedal (this should be done by an assistant).

12. Remove bolt..

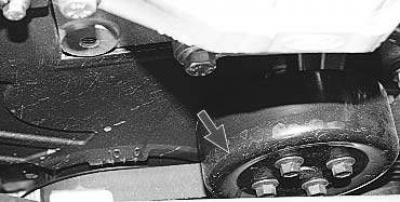

13.... and remove the crankshaft pulley.

14. While holding the water pump pulley from turning with a screwdriver, loosen the four bolts by rearranging the screwdriver one by one. Then finally unscrew the bolts..

15.... and remove the water pump pulley.

16. Turn out nine bolts of fastening of the top cover of a drive of the gas-distributing mechanism and remove a cover.

Note. This is how the holes for attaching the top cover are located.

17. Turn out three bolts of the lower cover of the gas-distributing mechanism..

18.... and remove the cover.

19. Remove the right support of the power unit (see «Replacing the suspension bearings of the power unit»).

20. Turn out two lateral bolts of fastening of an arm of the right support of a suspension bracket of the power unit …

21.... in the same way, unscrew the two front bolts and remove the bracket.

22. Loosen the tension of the timing belt, for which, with a finger or a screwdriver, overcoming the force of the spring, turn the movable roller bar clockwise until the holes in it and the roller bracket are aligned. Insert a pin of suitable diameter into the hole, fix the roller..

23.... and remove the timing belt.

Attention! Do not turn the crankshaft with the timing belt removed, as the valves will be damaged by the pistons.

24. Turn out a bolt of fastening of a tension roller and remove it.

Note. If you disassemble the timing mechanism drive only to replace the tension roller, the drive belt can not be removed.

25. Install the roller in the reverse order of removal, having previously fixed it with a beard.

Slide a new belt onto the exhaust camshaft sprocket. Tension the drive belt and slide it over the intake camshaft sprocket. Next, tighten the drive branch of the belt and put it on the crankshaft toothed pulley. Get the driven branch of the belt behind the tension roller.

26. Install the lower and upper timing belt covers and crankshaft pulley. Tighten the crankshaft pulley bolt in two stages:

- 1st - tighten the bolt to 45 Nm (4.5 kgf·m);

- 2nd - tighten the bolt by 90°.

27. Remove the fixing plate of the camshafts.

28. Turn out a fixing bolt of a cranked shaft from an aperture in the block of cylinders.

29. Engage neutral gear in the gearbox, turn the crankshaft two turns and stop it without bringing it to TDC by about 20°.

30. Screw the fixing bolt into the hole of the cylinder block and carefully tighten the crankshaft until it is fixed with the bolt.

31. Install the fixing plate on the camshafts. If the tool can be installed without difficulty, the timing belt is installed correctly. If the device cannot be installed (shifted valve timing), remove the belt, install the retainer and repeat the installation of the belt as described above.

32. If the timing belt is installed correctly, remove the fixing plate from the camshafts, unscrew the fixing bolt from the hole in the cylinder block, reinstall the plug of this hole, tightening it with a torque of 20 N·m (2.0 kgf·m), and install all previously removed parts in the reverse order of removal.

Visitor comments