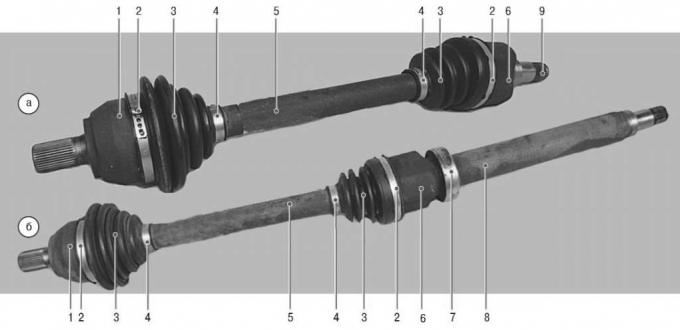

Pic. 6.6. Front wheel drives: a – left front wheel drive; b – right front wheel drive; 1 - external hinges of equal angular velocities; 2 - large clamps for fastening hinge covers; 3 – hinge covers; 4 – small collars of fastening of covers of hinges; 5 - drive shafts; 6 - internal hinges of equal angular velocities; 7 - intermediate support bearing; 8 - intermediate shaft; 9 - retaining ring

The Beerfield-type external joint consists of a body, a cage, a cage and six balls. Grooves are made in the hinge body and in the holder to accommodate the balls. The grooves in the longitudinal plane are made along the radius, which provides the required angle of rotation of the outer hinge. The splined tip of the outer hinge housing is installed in the front wheel hub and attached to it with a bolt.

The holder of the outer hinge is mounted on the splines of the shaft 5 and fixed on the shaft with a retaining ring.

The Tripod-type internal hinge consists of a body and three rollers on needle bearings, put on the trunnions of a three-spike hub. Grooves for rollers are made in the hinge body. The three-spike hub is fixed on the shaft with a retaining ring, the rollers allow the hub to move in the grooves of the hinge body in the axial direction, so that the drive can lengthen or shorten to compensate for the mutual movements of the suspension and the power unit. The splined tip of the drive internal hinge housing a of the left front wheel is fixed in the side gear of the differential with a spring lock ring 9, and the splined tip of the drive internal hinge housing b of the right front wheel is installed in the side gear without fixation, since the housing is fixed from axial movement by an intermediate support on the engine, the bearing 7 of which is pressed onto the intermediate shaft 8, made in one piece with the body of the inner hinge.

Balls of one sorting group are installed in the outer hinge. All parts of the hinge are selectively matched to each other, so it is not possible to repair the hinge by replacing individual parts. Spare parts supply only the hinge assembly, as well as a small repair kit that includes a retaining ring, boot, boot clamps, and in some cases grease.

The inner hinge is delivered to spare parts in the form of two repair kits: a large one, which includes all the details of the hinge, and a small one, similar to the outer hinge repair kit.

A special grease with molybdenum disulphide is used to lubricate the hinges (domestic analogue - SHRUS-4). The cavities of all hinges are protected from road dirt and water by rubber corrugated covers 3, fixed on the hinge bodies and on the drive shafts, respectively, with large 2 and small 4 clamps.

To ensure the stability of the car and improve its controllability when driving at high speed, the drive shafts of the left and right wheels are made of the same length, and the layout of the engine compartment of the car with a transverse arrangement of the power unit (the main gear is shifted to the left relative to the longitudinal axis of the vehicle) compensated by installing an intermediate shaft made in one piece with the body of the inner hinge of the right front wheel drive. Therefore, the drives of the right and left wheels are not interchangeable. The hinges of equal angular speeds of both drives are the same.

Note. The drive hinges are very durable, their design life is almost equal to the life of the car. However, in operation they are changed or repaired quite often due to damage to the protective covers. Such work is quite expensive and laborious. In order to save a lot of money, regularly check the condition of the protective covers of the hinges and immediately replace them at the slightest damage. If water or dust gets into the hinge through a damaged cover, it will fail after several hundred kilometers. The sealed hinge wears out extremely slowly.

Visitor comments