You will need: flat blade screwdriver, side cutters, beard, hammer.

1. Remove the front wheel drive assembly (see «Removal and installation of front wheel drives»).

2. Clean the parts and inspect the drive:

- the outer CV joint must rotate with a slight effort without jerking and jamming, radial and axial play. If present, replace the hinge;

- the inner hinge should move in the angular and axial directions with a slight effort, while jerking, jamming and radial play should not be felt. Otherwise, replace the inner joint;

- the protective covers of the outer and inner hinges must not have cracks or ruptures. Replace damaged cases;

- the wheel drive shaft must not be deformed. Replace the deformed shaft.

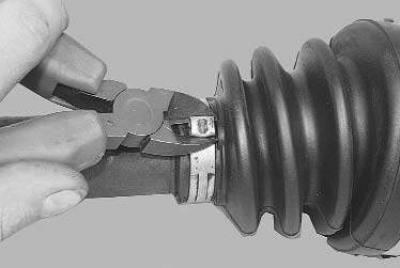

3. To replace the outer joint and its boot disconnect with a screwdriver or bite with side cutters the lock of the clamp for fastening the large cover of the outer hinge and remove the clamp.

Note. Clamps for fastening the protective covers of the constant-velocity hinges are disposable, replace them with new ones during assembly. As a rule, clamps are included in the kit of a new hinge.

4. Slide the protective cover off the hinge housing…

5.... and knock the hinge cage off the shaft with a hammer through the beard, overcoming the force of the retaining ring.

6. Remove the outer joint from the shaft splines.

Attention! Disassembly of the outer hinge is not allowed.

7. Remove the circlip by prying it out of the shaft groove with a screwdriver.

Note. When assembling, replace the circlip with a new one. As a rule, the ring is included in the kit of the new hinge.

8. Remove the small collar of the outer hinge cover in the same way as the large collar was removed (see point 3).

9. Remove the protective cover.

Note. When installing the hinge, replace the protective cover with a new one. Usually a boot is included with the new hinge.

10. Before installing a new outer joint, fill its cavity with grease (if the hinge has not been lubricated by the manufacturer) in an amount of about 100 g. And first fill the hinge body, and then evenly distribute the remaining amount in the corrugations of the cover.

Note. In the absence of a lubricant recommended by the manufacturer, domestic molybdenum grease SHRUS-4 can be used.

11. Install the outer hinge cover and hinge in the reverse order of removal. When installing the hinge on the shaft, press the hinge with hammer blows on the hinge shank through a soft metal drift until the hinge cage is fixed with the retaining ring.

Attention! Before securing the hinge boot with a large tie, use a screwdriver to pull back on the edge of the boot to equalize the air pressure inside and outside the boot.

Note. Clamps are marked with their diameter. The diameter of the large collar is 86.5 mm, the small one is 36.5 mm.

12. For disassembly and replacement of the inner joint and its boot remove the clamps securing the hinge cover to its body..

13.... and to the shaft.

14. If you disassemble the hinge to replace the cover and intend to install the old hinge, mark in any way (e.g. core, needle file or paint) mutual arrangement of the hinge body and the drive shaft.

15. Slide boot off hinge housing…

16.... and disconnect the body from the drive.

17. Mark the position of the pivot hub relative to the shaft (see point 14).

18. Prying off the retaining ring of the hinge hub with a screwdriver..

19.... remove the ring from the groove of the shaft.

20. Remove the hub with rollers from the splines of the shaft..

21.... and remove the protective cover from the shaft.

22. Wash all metal parts with kerosene until the old grease is completely removed.

23. Inspect the rollers, the hub and the interior of the housing. Seizures, dents and corrosion are not allowed. The rollers should rotate freely on their bearings, without jamming. If malfunctions are found, replace the hinge assembly.

24. Install the hinge cover on the shaft and secure it with a clamp.

25. Install the hinge hub on the splines of the shaft, aligning the marks made during disassembly, and fix it with a retaining ring.

26. Fill the cavity of the inner hinge with grease in an amount of about 100 g. And first fill the hinge body, and then evenly distribute the remaining amount in the corrugations of the boot.

Note. In the absence of a lubricant recommended by the manufacturer, domestic molybdenum grease SHRUS-4 can be used.

27. Install the hinge housing, aligning the marks made during disassembly.

28. Put a cover on the hinge body and secure it with a collar.

Attention! Before securing the hinge boot with a large tie, use a screwdriver to pull back on the edge of the boot to equalize the air pressure inside and outside the boot.

Note. Clamps are marked with their diameter. The diameter of the large collar is 80.5 mm, the small one is 41.7 mm.

Visitor comments