Attention! A special tachometer is required to check the RPM of a diesel engine.

Attention! Idling speed with high pressure fuel pump: DPC - 775±50 rpm; DPRC - 875±25 rpm.

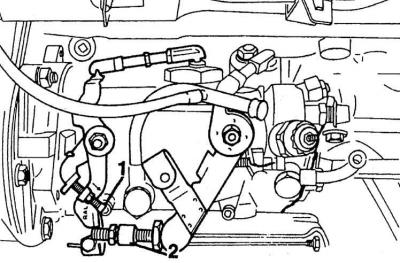

Engine Stop Lever Stop Screw (1) and idle speed screw (2)

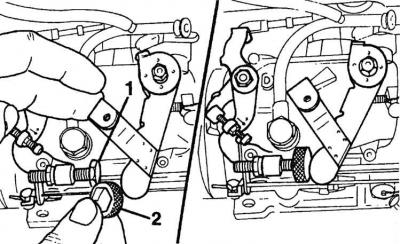

Installing the adjustment template Ford 23-016 (2) on the idle speed screw (1)

1. Warm up the engine until the radiator fan turns on.

2. Wait (with engine idling) until the fan turns off.

3. Turn off the engine and connect a special tachometer in accordance with the attached instructions.

4. Start the engine, while all electrical consumers must be turned off.

5. Unscrew the screw of the limiter of the engine stop lever until there is a gap between the screw and the lever (see fig. Engine Stop Lever Stop Screw (1) and idle speed screw (2)).

6. Check idle speed. To adjust the idle speed, loosen the lock nut and turn the adjusting bolt located near the fuel pump lever until the desired idle speed is obtained (see fig. Engine Stop Lever Stop Screw (1) and idle speed screw (2)).

7. Screw in the stop screw of the engine stop lever until it contacts the lever and the idle speed begins to increase.

8. Bring the engine to maximum speed (no more than 5 seconds), release the accelerator pedal and measure the time to decrease the rpm to idle. If the time exceeds 4 seconds, the rev reduction time must be adjusted.

9. Remove the accelerator cable from the high pressure fuel pump control lever.

10. Install adjustment template Ford 23-016 (2) on the head of the idle speed screw. If there is no template, install a 3 mm thick plate instead of the template (see fig. Installing the adjustment template Ford 23-016 (2) on the idle speed screw (1)).

11. Start the engine and measure the engine speed, which should be within 900±30 rpm. If necessary, set the desired speed with the engine idle speed adjustment screw.

12. Remove the template, connect the accelerator cable, check and, if necessary, adjust the engine idle speed.

13. If the speed decreases too rapidly, the engine tends to stall. In this case, unscrew the screw by 1/4 turn. If the speed decreases too slowly, screw the screw in 1/4 turn. In each of these cases, check and, if necessary, adjust the engine idle speed.

Visitor comments