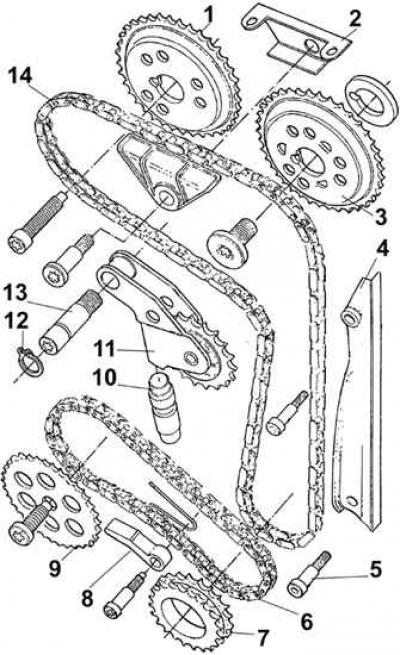

Timing gear drive

1 - camshaft sprocket that controls the intake valves, 2 - upper chain guide, 3 - camshaft sprocket that controls the exhaust valves, 4 - side chain guide, 5 - side chain guide mounting bolt, 6 - oil pump drive chain, 7 - drive chain sprocket, 8 - oil pump drive chain tensioner, 9 - oil pump sprocket, 10 - chain tensioner hydraulic tappet, 11 - timing chain tensioner, 12 - circlip, 13 - chain tensioner axle bolt, 14 - timing chain

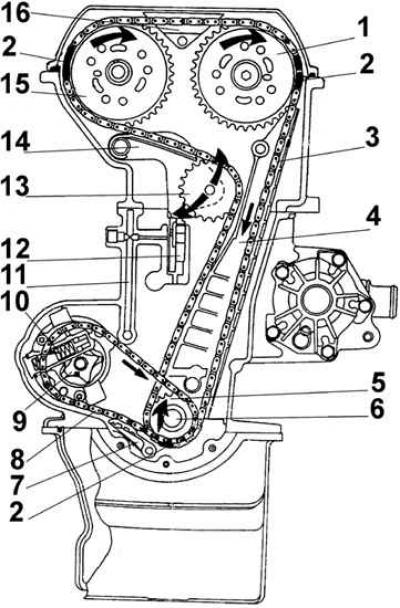

Gas distribution mechanism

1 - camshaft sprocket that controls the exhaust valves, 2 - copper installation elements on the side of the chain, 3 - timing chain, 4 - side chain damper, 6 - drive sprocket, 5 - crankshaft, 7 - oil pump drive chain tensioner, 8 - oil pump drive chain, 9 - oil pump rotor, 10 - pressure reducing valve, 11 - oil supply channel to the hydraulic pusher of the chain tensioner, 12 - hydraulic pusher of the chain tensioner, 13 - chain tensioner sprocket, 14 - chain tensioner lever, 15 - the camshaft sprocket that controls the intake valves, 16 - the upper chain guide

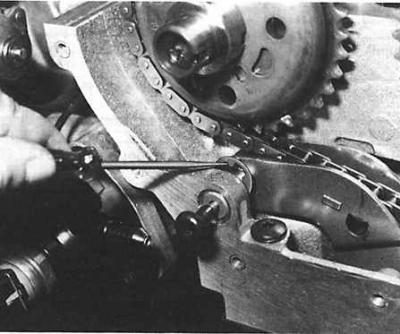

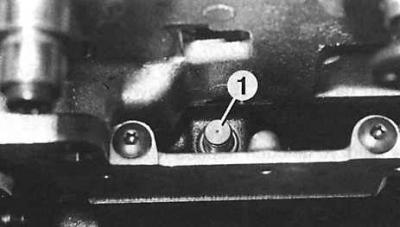

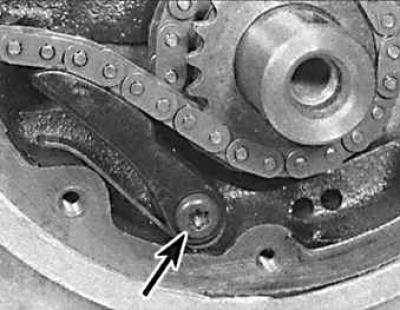

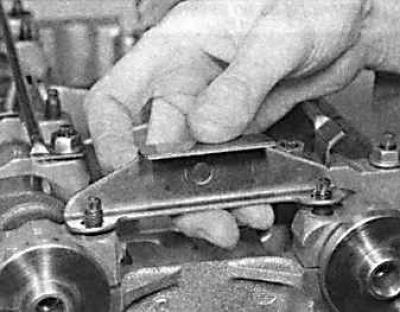

Removing the axis of the tensioner of the drive chain of the gas distribution system of the DOHC engine

The top picture is the removal of the retaining ring.

The bottom figure is the extraction of the tensioner axle.

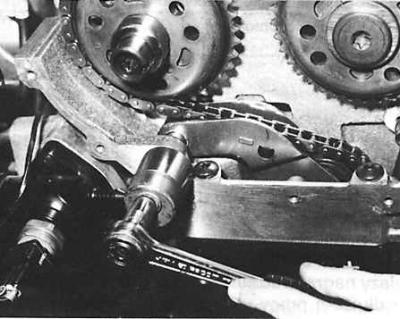

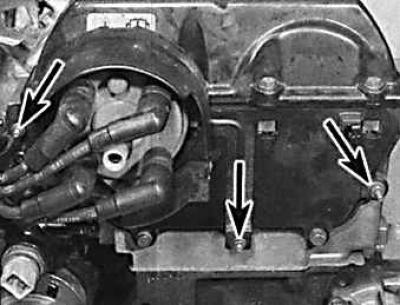

Location of the hydraulic pusher of the tensioner of the drive chain of the DOHC engine timing system

1 - hydraulic pusher

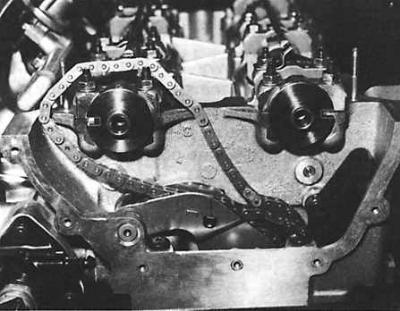

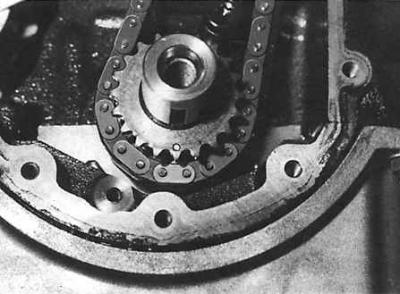

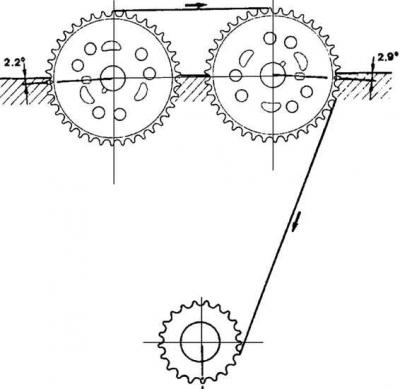

DOHC Engine Timing Installation

The top figure - the camshaft grooves must be directed in different directions.

The bottom figure is the crankshaft sprocket set marks and the copper-plated drive chain link.

Withdrawal

1. Remove ground wire from battery.

2. Remove the alternator drive and coolant pump V-belt.

3. Remove air filter.

4. On fuel injected vehicles, remove the air duct connecting the air filter to the throttle body.

5. Remove the high voltage wires from the spark plugs and unscrew the spark plugs.

6. Remove the ignition distributor cap together with high voltage wires.

7. Disconnect the crankcase breather hose from the cylinder head cover breather.

8. Disconnect the accelerator pedal cable. In an engine with a carburetor, unscrew the throttle cable together with the holder, and in an engine with fuel injection, disconnect the link from the throttle body after removing it from the plastic clamp side.

9. Remove the cylinder head cover.

10. Remove the ignition distributor.

11. Remove the top cover of the gas distribution mechanism.

12. Rotate the crankshaft in the direction of operating rotation until it reaches top dead center on the compression stroke of cylinder 1.

Attention! The crankshaft can be turned with a ring wrench by the middle bolt of the sprocket in the direction of its working rotation until the signs on the camshaft sprockets are set at the height of the upper plane of the cylinder head and in both camshafts are directed outward.

13. Loosen the crankshaft pulley bolt. To avoid turning the crankshaft when unscrewing the pulley, it is necessary to fix the flywheel by the teeth of the ring gear or engage fifth gear and the assistant press the foot brake all the way.

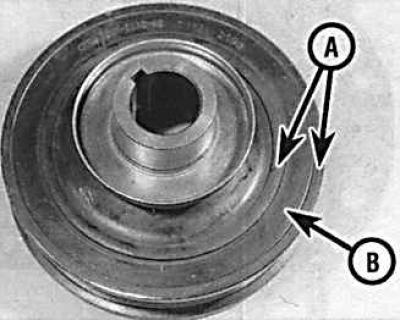

14. Partially unscrew the crankshaft pulley mounting bolt and use a puller to remove the pulley. The grips of the puller must rest against the metal part of the pulley (A - installation locations of the puller grips on the pulley). Do not place puller arms on a rubber surface (IN).

15. Unscrew the long lower alternator mounting bolt, then the upper bolt and remove the alternator.

16. Unscrew the central bolt securing the drive belt tensioner and remove the tensioner.

17. Unscrew the 11 mounting bolts and remove the bottom cover of the gas distribution mechanism. Remove rubber seal.

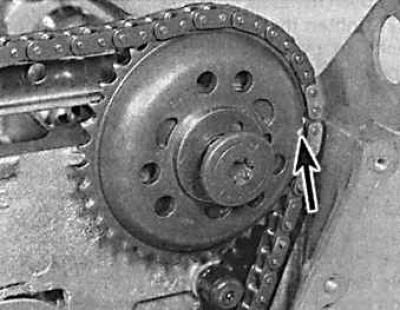

18. unscrew the bolt (indicated by an arrow) and remove the oil pump drive chain tensioner.

19. Unscrew the sprocket mounting bolt on the oil pump and remove the sprocket together with the chain.

20. Remove the top chain guide.

21. Unscrew the two bolts securing the lower chain guide and remove it upwards.

22. Remove the retaining ring from the axle of the timing chain tensioner lever and remove the tensioner lever.

23. Remove the axle of the timing chain tensioner lever using the M6x70 bolt and bushing.

24. Mark the camshaft sprockets and remove them.

25. Remove the sprocket and key from the crankshaft.

26. Pull the timing chain up.

Attention! To avoid collision of pistons and valves, when the timing chain is removed, do not turn the engine crankshaft.

27. Remove chain tensioner.

28. Remove the chain tensioner hydraulic pusher.

29. Disassemble the chain tensioner hydraulic tappet and drain the oil from it.

30. Pour fresh engine oil into the chain tensioner hydraulic tappet body, and using the special tool 21-145, assemble the chain tensioner as follows. Install the pusher housing with the hole up. Install the fixture on the pusher body, with the conical part of the fixture pointing upwards. Install the pusher plunger on the fixture and compress the assembly until a slight click is heard, while the pusher should lock in the down position.

Examination

Check the timing chain, sprockets and chain tensioner for wear and damage. If the plastic sprocket of the chain tensioner is worn out, the entire tensioner assembly must be replaced, since sprockets are not supplied separately.

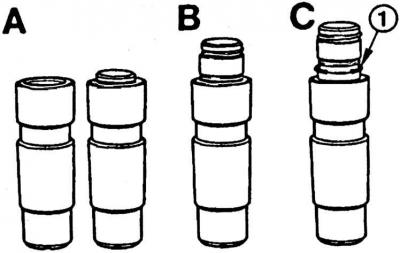

Hydraulic Pusher Chain Tensioner

A is the normal position of the plunger,

B and C - strong piston protrusion (pusher to be replaced),

1 - retaining ring

The position of the sprocket marks corresponding to the installation of the piston of cylinder 1 at top dead center in the compression stroke

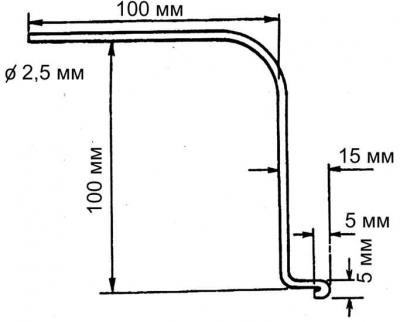

Special tool made of 2.5 mm wire to release the plunger of the chain tensioner pusher

Attention! There are copper elements on the timing chain that are used to properly position the timing mechanism when installing the chain.

Installation

1. Check that the crankshaft is in the position corresponding to the setting of the cylinder 1 piston at top dead center on the compression stroke, with the keyway pointing down.

2. Lower the chain from above into the casing, while the single copper link of the chain should be at the bottom.

3. Insert the key into the groove of the crankshaft.

4. Set the chain to the inner (big) sprocket while aligning the copper link of the chain with the mark on the sprocket.

5. Install the sprocket on the crankshaft, aligning the groove on the sprocket with the key, while the mark on the sprocket should be strictly below.

6. Insert the lower chain guide from above and screw it on with bolts, the threads of which are coated with an agent that prevents the bolts from unscrewing.

7. Install the chain tensioner hydraulic tappet. The plunger of the pusher should be at the level of the body or slightly protrude from it. If there is a significant protrusion of the plunger or a visible retaining ring on the plunger, the chain tensioner hydraulic pusher must be replaced.

8. Install the chain tensioner lever, the tensioner lever axle and secure it with a lock washer.

9. Check and, if necessary, reset the camshafts. The camshafts must be in a position corresponding to the cylinder 1 piston at top dead center on the compression stroke, and the alignment lugs for the sprockets must be in line with the top edge of the cylinder head and pointing outward.

10. Install the chain on the exhaust camshaft sprocket, aligning the mark on the sprocket with the middle of the chain section between the copper chain links.

11. Install the sprocket onto the camshaft. In this case, the mark on the asterisk (arrow) must be in line with the top edge of the cylinder head and point outward.

12. Screw in the sprocket bolt.

13. Install the chain on the intake camshaft sprocket, aligning the mark on the sprocket with the middle of the chain section between the copper chain links.

14. Install the sprocket onto the camshaft.

Attention! When installing the sprockets, the drive chain must be tensioned on the opposite side of the tensioner. In this case, the mark on the sprocket should be in line with the upper edge of the cylinder head and point outward.

15. Install the upper timing chain guide.

16. Rotate the crankshaft a few revolutions in the direction of engine rotation.

17. Check the position of the hydraulic tappet plunger. If the pushrod plunger sticks out too much from the housing, push it in by pressing the chain tensioner lever. If the pusher plunger is below the level of the upper edge of the pusher housing, a special tool made of 2.5 mm wire must be used to release the plunger.

18. Carefully pry up the tensioner lever, then insert a tool between the lever and plunger. Remove the screwdriver and release the plunger by pressing the chain tensioner lever and remove the tool.

19. Turn the crankshaft two revolutions in the direction of engine rotation and check the marks on the camshaft sprockets, which should be in line with the top edge of the cylinder head and pointing outward.

20. Turn the crankshaft one revolution in the direction of engine rotation and check the marks on the camshaft sprockets, which should be in line with the upper edge of the cylinder head and pointing towards each other.

21. Install the oil pump drive chain to the crankshaft sprocket, then install the drive sprocket and chain to the oil pump.

22. Install the oil pump chain tensioner.

23. Check the condition of the sealing ring in the top cover of the timing mechanism. If necessary, remove the old sealing ring and, using a tubular mandrel, install a new ring with the working edges directed towards the engine.

24. Install the top timing case cover with a new gasket (fastening nuts are indicated by arrows).

25. Install the cylinder head cover.

26. Check the condition of the O-ring in the bottom cover of the timing mechanism. If necessary, remove the old sealing ring and, using a tubular mandrel, install a new ring with the sealing lips directed towards the engine.

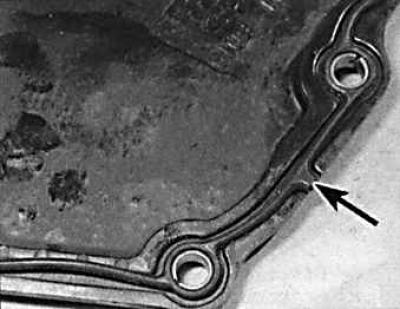

27. Install the lower timing cover with a new gasket without tightening the mounting bolts. ledge (indicated by an arrow) on the gasket should fit into the groove of the bottom cover.

28. Install the auxiliary belt pulley on the crankshaft and fix it with the old bolt, while centering the lower timing cover, and finally tighten the cover fixing bolts.

29. Unscrew the old bolt from the pulley and screw in a new one, tightening it to the required torque.

30. Install the auxiliary belt tensioner, making sure the tab on the back of the tensioner fits into the corresponding hole in the engine block.

31. Install generator.

32. Further assembly is carried out in the reverse order of disassembly.

Visitor comments