Another sign of piston wear is piston knock, similar to noise from the crankshaft, which must be distinguished from bearing knock. It can be heard clearly at low engine speeds with no load (e.g. at idle), and it is audible much less as the engine speed increases. Piston wear usually occurs at the skirt or bottom of the piston. It is also noticeable where the thickness of the skirt differs from normal.

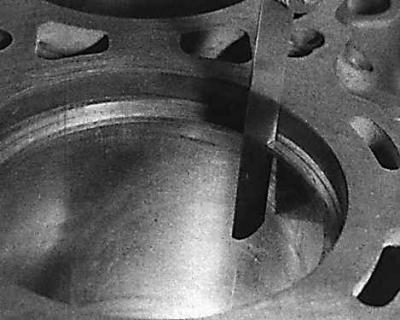

Checking the clearance in the piston ring lock using a feeler gauge

To check the wear of the piston rings, remove the rings from the piston, insert the rings into the cylinders from above, pushing them down about 40 mm using the piston (from which the rings were removed). Then measure the gap in the locks of the rings with a feeler gauge. If the gap exceeds the specified maximum, the rings need to be replaced.

Over time, the grooves in which the rings on the piston are located can also increase in size.

However, it rarely happens that the piston is worn only in the ring grooves, and the need for replacement for this reason alone is unlikely to arise. With any piston replacement, the weight of the four sets of pistons and connecting rods must be the same to maintain the overall balance of the engine.

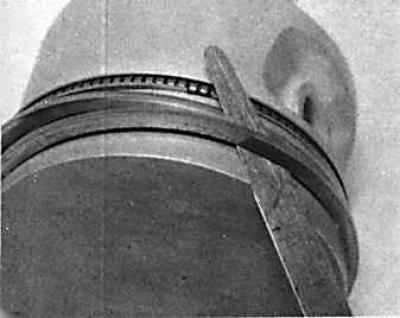

1. To remove the piston rings, carefully slide them towards the top of the piston so as not to scratch the aluminum alloy; never push them against the piston skirt. Piston rings are easily damaged if removed carelessly, so this operation must be carried out with extreme care. You can use old probes.

2. Lift one end of the piston ring to be removed from the groove and insert a feeler gauge under it.

3. Slowly run the feeler gauge around the piston, and when the ring is out of its groove, lift it up, the feeler gauge keeping it from slipping into the empty groove if there is one already.

4. Piston rings should always be removed through the top of the piston.

5. Check that the grooves for the piston end are clean.

6. The easiest way to install the rings is to use a feeler gauge, and the rings are installed one at a time, starting with the bottom oil scraper ring. The feeler gauge can then be moved down over the other piston ring grooves until the desired groove is reached. The piston ring is then moved off the feeler gauge into the desired groove.

7. Another method of inserting rings is to hold them with your thumb and forefinger. This method requires strong hands and great care, as the ring can be opened too far and broken.

Visitor comments