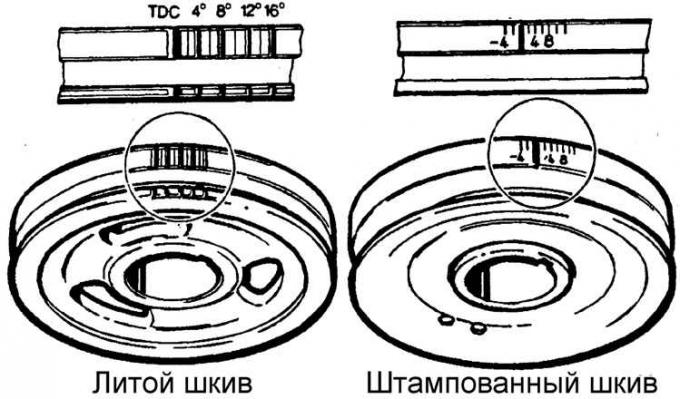

All engines except DOHC

OHC engine ignition timing scales

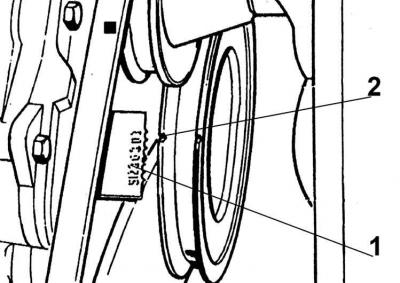

Ignition timing scale and V6 engine label

1 - scale for setting the ignition moment,

2 - pulley with a label

The ignition timing is set very precisely at the time of manufacture of the vehicle. Adjustment is necessary after removing the ignition distributor or timing belt drive.

Before checking, the following conditions must be met:

- the engine must be warm;

- on engines with a carburetor, the vacuum pipe must be disconnected from the manifold and the manifold openings plugged;

- idle speed must be below 900 rpm;

- disconnect and insulate the octane corrector wire.

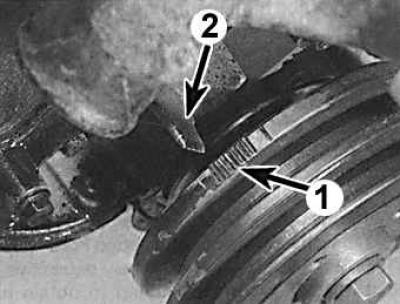

1. Clear alignment marks. On OHC engines, the ignition timing dial (1) located on the crankshaft pulley, and the pointer (2) on the cover must be aligned with the corresponding mark on the pulley.

Attention! There are two alternative pulley types with different marks. On V6 engines there is one notch on the pulley and the ignition timing dial is located on the cover.

3. Connect the stroboscope to the high-voltage wire of cylinder 1 and then in accordance with the instruction manual.

4. Start the engine in idle mode and direct the light from the strobe light to the marks. The marks must be in place and aligned with the pointer at the desired ignition setting angle.

5. To adjust the ignition timing, stop the engine, loosen the ignition distributor mounting bolt, turn the distributor and tighten the mounting bolt. To advance the ignition, turn the distributor counterclockwise and vice versa. Start the engine and recheck the ignition timing.

DOHC engine

The ignition timing is set by the ESC II or EEC IV and no further adjustment is possible.

Visitor comments