Attention! Uneven and unstable idle speeds do not always indicate the failure of the stepper motor. First you need to check the reliability of contact between the plunger and the set screw.

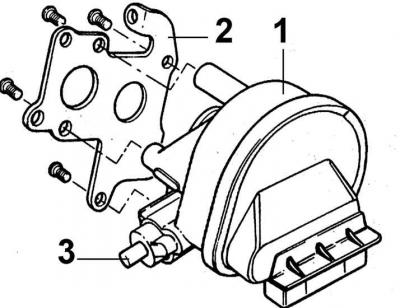

Stepper motor, suspension plate and plunger

1 - stepper motor, 2 - suspension plate, 3 - plunger

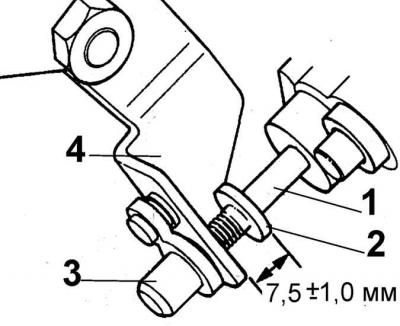

Initial Throttle Lever Screw Adjustment

1 - stepper motor plunger, 2 - adjusting screw head, 3 - cap, 4 - throttle lever

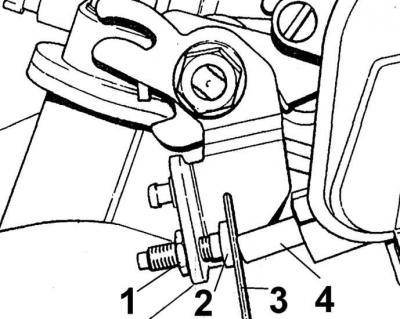

Checking the correct adjustment of the stepper motor

1 - locknut, 2 - adjusting screw, 3 - probe blade, 4 - plunger

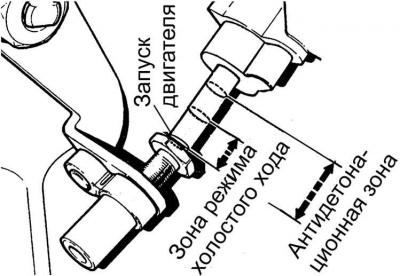

Stepper motor plunger positions

1. Remove the negative cable from the battery.

2. Remove air filter.

3. Disconnect the multi-pin connector from the stepper motor.

4. Remove the four screws that secure the stepper motor mount to the carburetor.

5. Remove the engine along with the suspension.

6. Install the stepper motor, tighten the four screws and connect the connector.

7. Make an initial adjustment of the throttle lever screw so that the screw head is 7.5 mm from the lever.

8. Connect the air cleaner vacuum hose. Place the air filter aside so that you have access to the carburetor and stepper motor.

9. Connect the tachometer according to the instructions.

10. Connect battery.

11. Start the engine and check and, if necessary, adjust the quality of the mixture.

12. Turn off all electrical consumers. If the idle speed control wire is grounded, temporarily insulate it. Check that the automatic transmission gear selector is in the N or P position.

13. Increase engine speed to 2500 rpm and return to idle, then repeat the cycle. Insert a feeler blade with a thickness of 1.0 mm between the stepper motor plunger and the set screw, while the motor speed should be within 875±25 rpm.

14. To carry out the adjustment, remove the protective cap, loosen the locknut and turn the adjusting screw to set the required idle speed.

15. Remove the chip blade, stop and restart the motor while observing the movement of the stepper motor plunger. After stopping the engine, the plunger should move to the anti-knock zone (get into the stepper motor), and after a few seconds move to the throttle lever.

16. Disconnect the tachometer and replace the air filter.

17. Recheck the quality of the mixture.

18. Reconnect the idle speed control wire.

Visitor comments