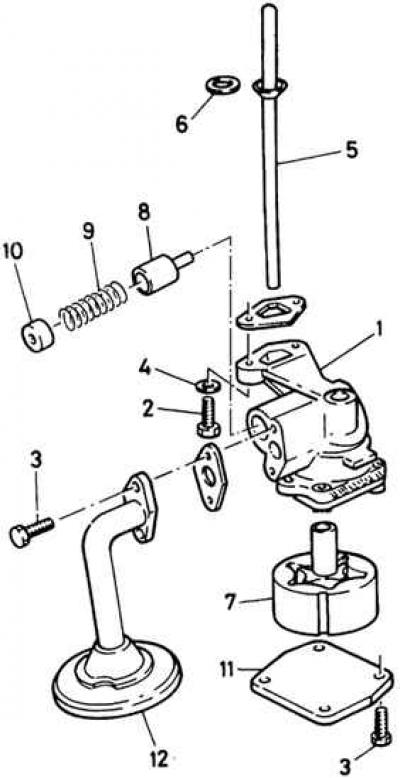

Oil pump

1 - housing, 2, 3 - bolts, 4 - lock washer, 5 - drive shaft, 6 - washer, 7 - rotors, 8 - plunger, 9 - spring, 10 - plug, 11 - cover, 12 - intake tube with mesh filter

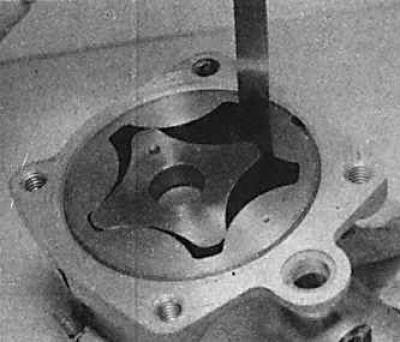

1. Check pump for wear. If one rotor needs to be replaced, both rotors must be replaced as they are a matched pair. If the rotors are serviceable, before proceeding with disassembly, mark the front side of the outer rotor for proper reassembly.

2. Mark the relative position of the oil pump cover and the pump housing, then unscrew and remove the bolts and spring washers. Remove cover.

3. Carefully remove the rotors from the housing.

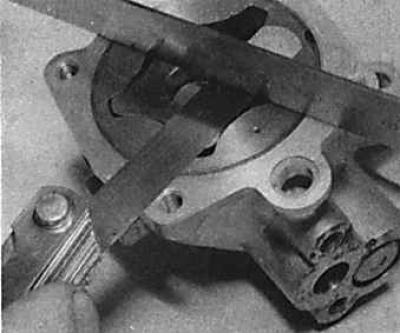

4. Using a punch, punch a hole in the sealing plug of the pressure reducing valve (install a new plug).

5. Screw in the self-tapping screw and use an open end wrench to remove the sealing plug.

6. Thoroughly clean all parts in petrol or kerosene and wipe dry with a cloth. Check the gaps with a steel ruler and a set of feeler gauges. The most important are the gaps: between the protrusions of the central rotor and the convex parts of the outer rotor; between the rotor and the pump casing; between both rotors and the flat end cap.

7. Check the gap between the protrusions of the rotors using a set of feelers, the gap should be in the range of 0.05–0.20 mm.

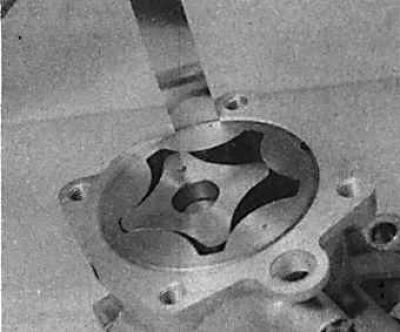

8. The gap between the outer rotor and the pump housing should be within 0.15–0.30 mm.

9. Install a steel ruler on the end of the pump and measure the gap between the rotors and the ruler. The gap of each rotor should be within 0.03–0.10 mm.

10. In the event that only the end clearance values exceed the required values, the clearances can be reduced by removing the rotors and lapping the end surface of the housing on the lapping plate until the required clearances are reached. It should be emphasized that the end surface of the housing must remain flat and perpendicular to the axis of the rotor. If the other two clearances do not match the values given in subsection 3.3.1, the pump must be replaced with a new one.

11. Thoroughly clean all parts, reinstall pressure reducing valve and spring and lightly lubricate with engine oil.

12. Install a new sealing plug using a bead of the appropriate diameter (flat side out) level with the surface of the inlet pipe flange.

13. Lubricate both rotors with engine oil and install in the housing. Install the oil pump cover and fix it with four bolts, tighten them gradually diagonally to the required torque.

14. Install the drive shaft into the rotor drive shaft and check that the rotor turns freely.

15. Reinstall the suction pipe and strainer.

Visitor comments