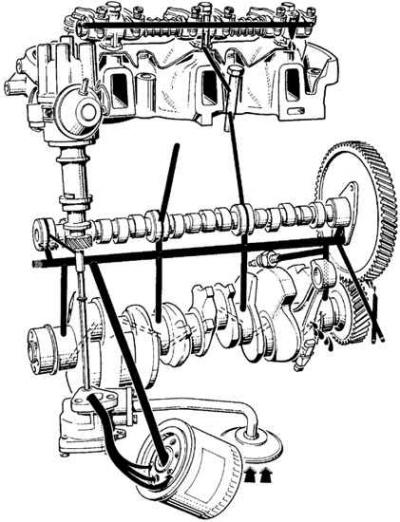

Engine lubrication system

A pressed steel oil pan mounted underneath the crankcase serves as a reservoir for the engine oil. With the help of an oil pump, the oil from the sump through the strainer and the intake pipe is sent to the full-flow oil filter.

The filtered oil is directed by a stream from the center of the filter element and through a small channel on the right side enters the oil pressure sensor and the main line (on the left side of the crankcase) through the transverse channel.

Four channels bring the main line to the four main bearings, the camshaft bearings, in turn, also communicate with the main bearings. Oil is supplied to the connecting rod bearings through diagonal channels from the nearest crankshaft main bearings.

As the crankshaft rotates, oil enters through bores in the bearings of the lower connecting rod heads, thereby providing splash lubrication to the piston pins and sides of the cylinders that receive lateral pressure. The timing gears are also splash lubricated through the lubrication channels.

From the neck of the third bearing of the crankshaft, oil in intermittent mode under pressure flows through the channel in the cylinder block and cylinder head to the axes of the valve rocker arms. The oil then returns to the engine sump through large passages in the cylinder block and cylinder head.

Visitor comments