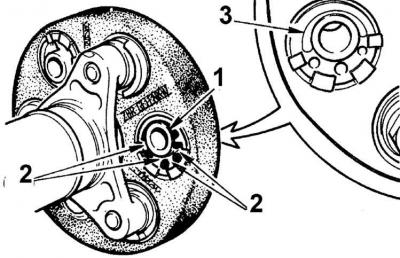

Rubber coupling of propeller shaft GAF 30

1 - metal coupling, 2 - rubber dampers, 3 - rubber lining

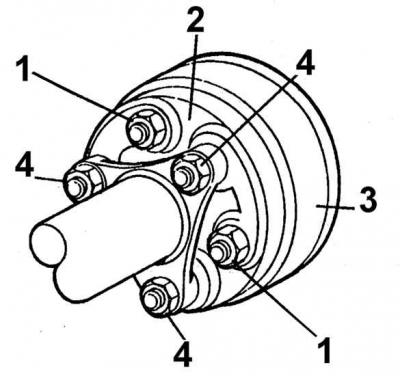

Rubber coupling of propeller shaft GAF 41

1 - coupling nuts with damper, 2 - GAF coupling, 3 - damper, 4 - shaft-coupling nuts

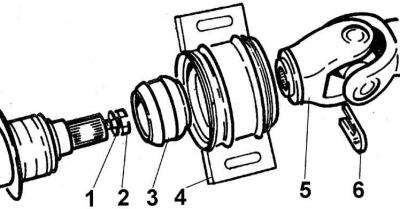

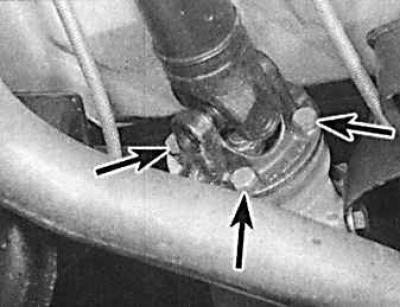

Removing the intermediate bearing

1 - retaining ring, 2 - bolt, 3 - intermediate bearing, 4 - intermediate bearing housing, 5 - cross joint, 6 - mounting U-plate

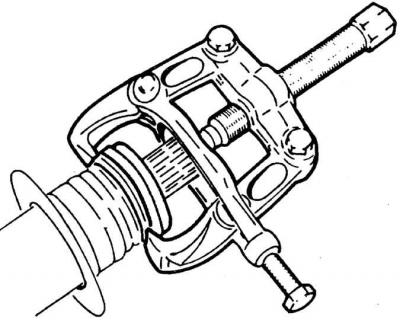

Removing the intermediate bearing with a puller

1. Install the car above the viewing channel or on a lift.

2. Mark the mutual position of the cruciate joint and the flange of the final drive gear and disconnect the propeller shaft from the rear axle (rear flange mounting bolts are indicated by arrows). Unscrew the intermediate bearing housing, marking the position of the gaskets between the bearing housing and the car body (these designations are useful when installing the cardan shaft and its intermediate bearing).

3. Detach the driveshaft from the gearbox, being careful not to damage the O-ring at the rear of the crankcase. After removing the shaft, the hole in the rear of the gearbox housing should be plugged with a plug or front tip of the failed driveshaft to prevent oil from leaking out of the gearbox.

Installation

1. Remove the plug from the hole in the rear of the gearbox housing. Check the installation of the sealing ring on the rear of the gearbox housing and insert the front end of the propeller shaft into it, being careful not to damage the edges of the sealing ring.

2. Install the intermediate propeller shaft bearing, placing the appropriate gaskets under it in accordance with the symbols applied during disassembly (without tightening the bolts).

3. Connect the propeller shaft to the main gear drive flange in accordance with the previously applied relative positions. Install new gaskets to keep the bolts from loosening.

4. Rotate the cardan shaft to install the intermediate bearing and tighten the mounting bolts to the appropriate torque.

5. Check and, if necessary, top up the amount of oil in the gearbox.

Gearbox type MT 75

The difference between the cardan shaft used with the gearbox type MT 75 lies in the fastening of the cardan shaft to the gearbox.

Unscrew the three nuts securing the propeller shaft rubber coupling to the gearbox output shaft and remove the propeller shaft. Two types of rubber coupling GAF 30 or GAF 41 are used.

Coupling GAF 30

The coupling studs must not rotate when applying a torque of 80 Nm. If the stud turns when less torque is applied, it must be unscrewed and installed as follows.

1. Clean the threads in the gearbox flange.

2. Apply two drops of anti-threading agent to the threads of the holes (hole on both sides), immediately screw on the pin and allow the product to harden for 30 minutes.

3. Check the condition of the rubber coupling for mechanical damage and cracks. In the presence of cracks, the cardan shaft must be replaced, since the cardan shaft is balanced with the clutch as a whole. When replacing the cardan shaft, install a shaft with a GAF 41 coupling.

4. Attach clutch to gearbox using new nuts.

Coupling GAF 41

Unscrewing, checking and installation are carried out in the same way as for the GAF 30 coupling, except that the studs must not turn when a torque of 110 Nm is applied.

Visitor comments