Air from the brake system is removed by pumping it with the brake pedal; an assistant is required to complete this work. Depending on the model and equipment, two different anti-lock braking systems are installed on SCORPIO vehicles (ABS), the removal of air from which is carried out in different ways. Therefore, in accordance with chapter "Anti-lock braking system (ABS)" you must first determine which system is installed on the car, see p. 110.

Caution: When venting, watch the fluid level in the expansion tank. The liquid level must not fall below the MIN·mark If one of the chambers of the expansion tank is completely empty (for example, due to leaks in the system or due to the fact that you forgot to top up the brake fluid in a timely manner), then the removal of air from the brake system must be carried out at the service station. At the service station, the process of bleeding the ABS hydraulic unit is controlled using a diagnostic tool to read fault codes.

Brake system TEVES MK II

Air removal

The entire system must be bled of air, even if only one brake caliper has been replaced.

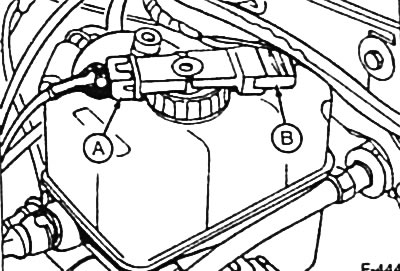

Disconnect multi-pin connectors -A, B- at expansion tank and unscrew tank cover.

Top up the fluid level in the expansion tank to the MAX mark. When removing air, observe the liquid level in the compensation tank. The liquid level must not fall too low, otherwise air will enter the system through the tank. Always drink only new brake fluid!

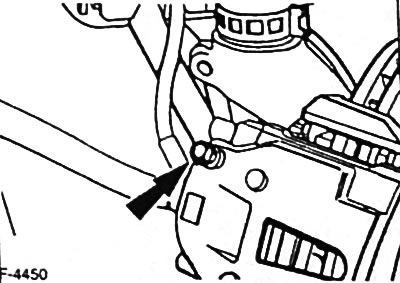

Remove dust cap from bleeder valve -arrow- at front left brake caliper and fit ring spanner to valve.

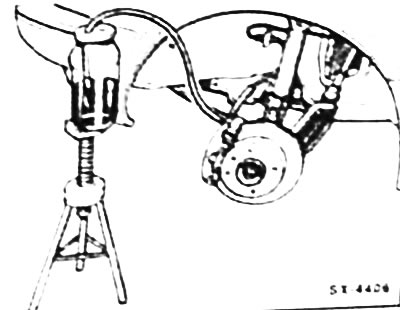

Clean the bleed valve, put a clean hose on it, insert the other end into a container half filled with brake fluid (suitable hose and container can be purchased from car accessories stores). The container should be located about 30 cm above the bleed valve so that the hose is filled and air does not enter the brake caliper through the valve threads.

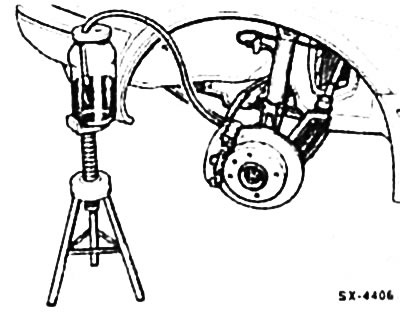

Attention: Contrary to the picture in the figure, the vehicle must be standing with its wheels on level ground when bleeding. Carefully open the bleed valve to avoid damage. It is recommended to spray the valve with a rust remover about two hours before bleeding. If the valve does not open. work on removing air should be entrusted to a service station.

Have an assistant depress the brake pedal and hold it down.

Open the bleeder valve a full turn with the ring spanner.

Tighten the bleeder valve and release the brake pedal.

Repeat the bleed process until no more air bubbles enter the container together with the brake fluid flowing out and until a lighter colored fluid begins to emerge.

Tighten the bleeder valve and put on the dust cap. Similarly, bleed the air from the brake caliper of the right front wheel.

Tighten the bleeder valve and put on the dust cap.

Remove dust cap from bleeder valve -arrow- at rear left brake caliper and fit ring spanner to valve. Clean the air bleed valve, put a clean hose on it, insert the other end of which into a container half-filled with brake fluid.

Open the bleeder valve a full turn with the ring spanner.

Ask an assistant to press the brake pedal all the way down and hold it down.

Switch on the ignition by turning the ignition key to position II.

Attention: Do not start the engine.

When the ignition is switched on, the ABS brake hydraulic pump starts to work. As soon as the brake fluid reaches the pump, the pump tone changes from high to low.

Attention: Do not operate the pump continuously for more than two minutes. If the hydraulic pump has been running for more than two minutes, turn the ignition key to position 0 and let the pump cool down for at least ten minutes.

Safety note: When bleeding the rear brake hydraulic drive, release the bleeder valve carefully, as the hydraulic actuator may be under very high pressure.

The process of removing air through the valve should last until air bubbles stop flowing together with the brake fluid flowing into the container and until a lighter-colored liquid begins to emerge (new).

Tighten the bleeder valve and put on the dust cap.

Release the brake pedal and wait until the hydraulic pump stops.

Remove the dust cap from the bleed valve at the right rear brake caliper and attach a ring wrench to the valve. Clean the bleed valve, put a clean hose on it, insert the other end into a container half filled with brake fluid.

The process of removing air through the valve should last until air bubbles stop flowing together with the brake fluid flowing into the container and until a lighter-colored liquid begins to emerge (new).

Ask an assistant to depress the brake pedal halfway and hold it in this position.

Tighten the bleeder valve and put on the dust cap.

Release the brake pedal and wait until the hydraulic pump stops.

Turn the ignition key to position 0.

Top up the fluid level in the expansion tank to the MAX mark.

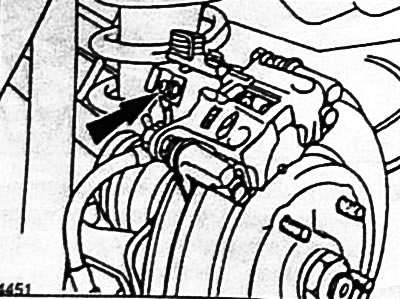

Screw on the cover of the compensation tank and make sure that the retaining tab of the tank is correctly inserted into the cover.

Connect the multi-pin connectors at the tank cover.

Have an assistant depress the brake pedal several times and check that no brake fluid is escaping through the bleed valve.

Brake system TEVES MK IV

If air must be removed from the entire system, then this is done separately on each wheel brake. This occurs when the brake fluid is changed to new or when air has entered each individual brake cylinder.

The sequence of operations when removing air: 1 - front left brake caliper; 2 - front right brake caliper, 3 - rear left brake caliper; 4 - rear right brake caliper.

In the event that only one caliper has been replaced or repaired, it is usually sufficient to bleed the air from the brake cylinder of this caliper.

Before bleeding, top up the liquid level in the expansion tank to the MAX mark.

Caution: When venting, watch the fluid level in the expansion tank. The liquid level must not fall too low, otherwise air will enter the system through the tank. Always top up with new brake fluid!

Remove the dust cap from the brake cylinder bleed valve. Clean the bleed valve, put a clean hose on it, insert the other end into a container half filled with brake fluid (suitable hose and container can be purchased from car accessories stores). The container should be located about 30 cm above the bleed valve so that the hose is filled and air does not enter the brake caliper through the valve threads.

Attention: Contrary to the picture in the figure, the vehicle must be standing with its wheels on level ground when bleeding. Carefully open the bleed valve to avoid damage. It is recommended to spray the valve with a rust remover about two hours before bleeding. If the valve does not open. work on removing air should be entrusted to a service station.

Open the bleeder valve a full turn with the ring spanner.

Have an assistant depress the brake pedal and release it quickly. As a result, brake fluid or, respectively, air is pumped into the container.

Wait a little while the brake master cylinder piston returns to its original position.

Press the brake pedal again and quickly release it again. Repeat this bleed process until no more air bubbles enter the container with the brake fluid flowing out and until a lighter-colored fluid begins to emerge (new).

Tighten the bleeder valve with the brake pedal depressed.

Remove the hose from the bleed valve and put the dust cap on the valve.

Similarly, bleed the air from the brake caliper of the right front wheel.

Safety note: When bleeding the rear brake hydraulic drive, release the bleeder valve carefully, as the hydraulic actuator may be under very high pressure.

Similarly, bleed the air from the rear axle brake calipers. First from the rear left, then from the rear right.

After removing the air, top up the brake fluid level in the compensation tank to the MAX mark and screw on the cover of the compensation tank.

Attention, perform a security compliance check:

- Are the air vent valves tight?

- Is there enough fluid in the brake system?

- With the engine running, perform a leak test. To do this, act on the brake pedal with a force of 200 to 300 N for about 10 seconds (from 20 to 30 kg). Do not release the brake pedal. Check all connections for tightness.

Finally, perform a few stops on a street with little traffic.

Take old brake fluid to your local special waste collector.

Visitor comments