Models since 9/94

Withdrawal

Mark the position of the front wheel on the hub with paint. Thanks to this, the balanced wheel can be installed again in its original position. When loosening the wheel nuts, the car must stand on the site. Raise the front of the car on jack stands and remove the front wheel.

Loosen the nut of the locking bolt for the control arm ball joint at the swivel bearing and remove the locking bolt.

Pull the ball joint pin of the control arm downwards out of the swivel bearing.

Attention: Make sure that the rubber seal of the ball joint is not damaged. Wrap the ball joint with a rag.

Unscrew bolts at transverse link supports and remove transverse link.

Installation

Tighten bolts at transverse arm supports.

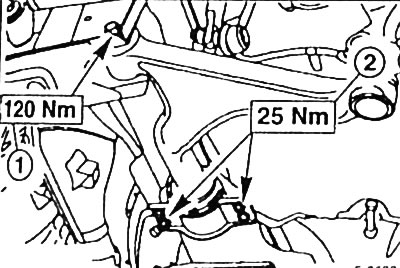

Caution: Tighten bolts -1- and -2- fully only after the vehicle is on wheels.

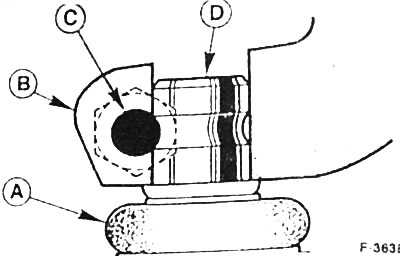

Models from 9/94: Press the ball joint of the control arm from below into the swivel bearing -B- as far as it will go. Insert the bolt -C- from the front, it must pass through the groove on the pin -D- of the control arm ball joint.

Attention: The head of the bolt must be facing the direction of the vehicle. Tighten the new self-locking bolt nut to 80 Nm, A - dust seal.

Attach the front wheel so that the marks applied before removing coincide. First, apply a thin layer of grease for rolling bearings to the place where the rim fits on the wheel hub. Do not lubricate the threads of the wheel studs. Screw on wheel nuts. Lower the vehicle and tighten the wheel nuts crosswise to 100 Nm.

Put the car over a viewing hole or on a flyover.

The car must be on wheels. Tighten support bolt -1- to 120 Nm and tighten bolts -2- to 25 Nm, see figure F-3692 above.

As soon as possible, check and, if necessary, adjust the parameters of the running gear, see p. 109.

Visitor comments