Withdrawal

Raise the car on the goats.

Remove exhaust system see p. 80.

Vehicles with catalytic converter: Remove heat shield from underbody.

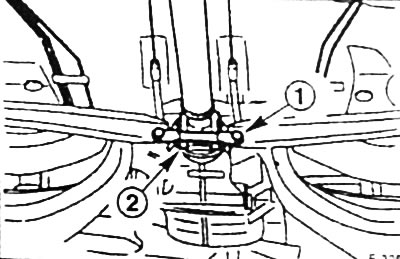

Models from 9/94 unscrew the fastening of the cross member -1- of the rear axle in order to gain access to the flange -2- of the propeller shaft.

Unfasten propeller shaft at the intermediate bearing at the bottom of the body and at the flange of the final drive of the rear axle. When releasing the bolts at the flange, ask an assistant to depress the brake pedal.

Gearbox MT-75 (models since 1989)

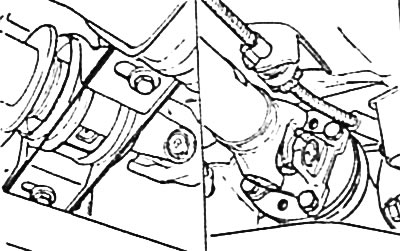

Unscrew the fastening to the damper of the coupling screwed to the cardan shaft with rubber elastic elements.

Attention: Loosen the fastening of the coupling to the cardan boulder.

If the damper is made with splined studs, when releasing the fastening nuts, hold the studs with a standard slotted socket wrench.

Remove the cardan shaft as an assembly.

Gearbox N (models before 1989): Remove the propeller shaft from the transmission extension.

Attention: To prevent oil from leaking out of the gearbox, insert a plug into the hole in the gearbox.

Installation

Gearbox N: Remove the plug from the hole in the extension of the gearbox and connect the propeller shaft to the splines of the drive shaft. Fit propshaft to final drive flange and intermediate bearing and fasten by hand with bolts.

Attention: Do not forget to install washers at the intermediate support.

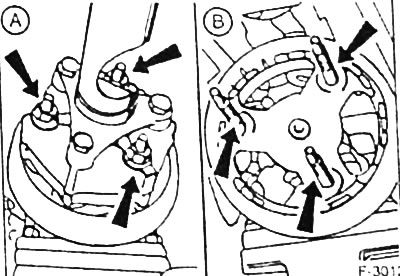

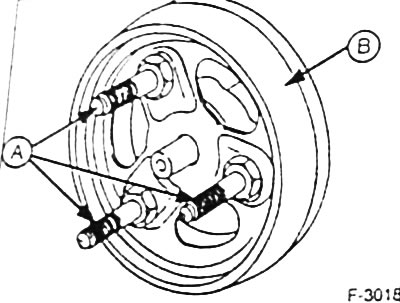

MT-75 gearbox, damper studs are splined

Check the condition of the rubber bridges -B- of the coupling on the propeller shaft. If the jumpers are cracked, then the cardan shaft assembly with the clutch must be replaced.

Attention: The propeller shaft is balanced as a clutch assembly and the parts of this assembly cannot be replaced individually. Cracks in the coupling body in area -C- are of no significance. A is a metal bushing.

Attach propshaft to final drive flange and fasten by hand with bolts. Slide the rubber shaft sleeve over the studs and fasten the shaft by hand with bolts at the intermediate support.

Attention: Do not forget to install washers at the intermediate support.

Screw on the nuts securing the rubber coupling and tighten to 80 Nm.

Attention. Check if the studs are firmly seated. If the studs loosen or turn when tightening the fastening, then the rubber sleeve fastening should be released again and the studs should be fastened properly.

To secure the studs, they must be unscrewed and the threads on the studs and in the damper cleaned.

Apply 2 drops of Locate 270 anti-twisting agent to the threads of the studs in a 180°arc.

Screw in the studs and tighten to 90 Nm.

Attention: Do not screw slotted studs into the damper instead of hexagonal studs and vice versa.

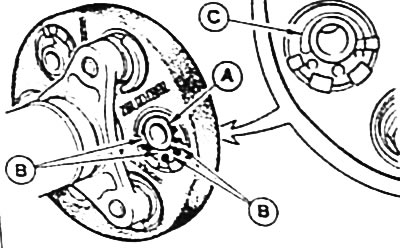

Gearbox MT-75, damper studs have a hexagon (old version)

Tighten studs -A- for damper -B- to 120 Nm.

Attach propshaft to final drive flange and fasten by hand with bolts. Slide the rubber shaft sleeve over the studs and fasten the shaft by hand with bolts at the intermediate support.

Attention: Do not forget to install washers at the intermediate support.

Screw on the nuts securing the rubber coupling and tighten to 80 Nm.

Attention. Slotted studs must not be screwed into the damper instead of hex studs and vice versa.

Tighten bolts for propshaft intermediate bearing to 20 Nm.

Tighten bolts for propshaft at rear axle to 65 Nm. When tightening the bolts at the flange, ask an assistant to depress the brake pedal.

Models since 9/94. Tighten the 2 screws securing the rear axle cross member to 50 Nm.

Vehicles with catalytic converter: Tighten the catalytic converter heat shield to the underbody.

Install exhaust system see p. 80.

Lower the car.

Visitor comments