Withdrawal

Remove wheel hub.

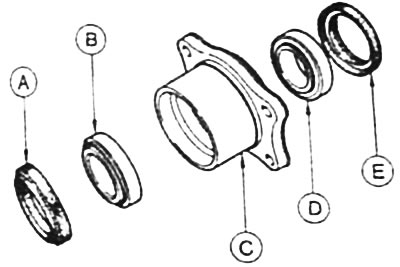

Using a screwdriver, pull out the radial seals -A, E- from the hub -C-. Remove both tapered roller bearings -B, D-.

Knock out the bearing races with a copper rod. At the same time, attach the rod along the circumference to the opposite sides of the clip in order to prevent its distortion.

Caution: To avoid burr formation on the clip, use only a flawless rod.

Installation

Clean the spaces in the hub for the bearing races and radial seals.

If burrs form on the seats when knocking out the clips, they should be removed.

Carefully drive the outer and inner races of the bearing up to the stop with a suitable short tube. The outer diameter of the pipe must match the diameter of the holder.

Tapered roller bearing filled with bearing grease (e.g. Liqui Moly LM-320). In this case, all cavities between the rollers must be filled with grease.

Caution: Do not fill the space between the bearings with grease. Excess grease in the hub will be squeezed out through the radial seal.

Insert outer bearing -B- and drive in a new radial seal using a suitable pipe. Prefill the space between the sealing lips with grease. This reduces wear on the sealing lips.

Install inner bearing -D- with radial seal -E- in the same way.

Install the wheel hub.

Visitor comments