Examination

Check tire pressure, adjust if necessary.

Carry out a test drive. As accurately as possible, determine the boundaries of the manifestation of a malfunction, the range of speed, road conditions, cornering and straight ahead.

Raise the car on the goats.

Check the centering of the middle part of the rim. In this case, the wheel hub or brake drum must protrude above the disc wheel console or at least end with it. Otherwise, replace the rim.

Check wheel suspension. To do this, check the rubber-metal bearings, joints, shock absorbers and rims for impeccable condition.

Remove and clean wheels. At the same time, stones should also be removed from the tread.

Examine tires for wear spots. These are places with low tread height, which can occur as a result of wheel blocking during braking.

Check the height of the tread patterns of individual tires and compare them with each other. If the front and/or rear tires show abnormal wear, the front and rear chassis must be determined and adjusted if necessary. In this case, the adjustment of the toe-in of the wheels must be carried out according to the upper limit of the tolerance.

Attention: To determine the parameters of the running gear, you need the appropriate measuring equipment, which, as a rule, is only available at the service station.

Carry out a test drive and check if there are still problems.

Checking the radial and lateral runout of the wheels

With the vehicle raised, attach the linear travel indicator first to the tread tread and then to the sidewall of the tire. Turn the wheel slowly by hand and read the readings from the indicator scale. Mark the point of maximum radial runout on the tire with chalk.

The prescribed wheel runout values are: the maximum radial runout is 2.0 mm, the maximum lateral runout is 2.0 mm.

If these values are not maintained, balance the wheels on a stationary balancing machine. In this case, the wheels, as on a car, must be centered in the middle. Conical jigs that center the wheel relative to the center hole are not allowed. The permissible residual unbalance in both balancing planes is 5 grams.

Elimination of radial runout

Deflate the tire and press the tire bead against the base of the rim.

Rotate the tire on the rim by 120°.

Inflate the tire and check the radial runout again.

If the measured value exceeds the prescribed value, rotate the tire on the rim by another 120°and check the radial runout.

If the specified maximum value is observed, balance the wheel.

Checking the radial and lateral runout of the rim

Center the rim without tire in the middle part on the balancing machine or install it on the wheel hub of the car. Install a linear travel indicator.

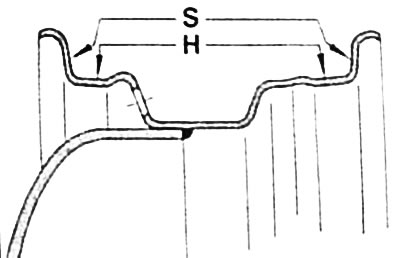

Take measurements of radial and lateral runout of the rim Radial runout (non-cylindricality) is measured on the shoulder of the rim, and the lateral runout is measured on the side surface of its shoulder. In this case, local deviations in the readings of the dial indicator, caused by elevations or depressions in the rim material, should not be taken into account.

Prescribed runout values for the steel rim: the maximum radial runout is 2.0 mm; maximum lateral runout - 2.0 mm.

The prescribed runout values for light alloy rims are: the maximum radial runout is 0.5 mm; maximum lateral runout - 0.8 mm.

If the measured runout values exceed the prescribed values, replace the rim.

Mounting wheels on a car

At the car raised on the goats, attach the wheels so that the place of maximum radial runout is at the top. In this position, tighten the wheel nuts crosswise to 100 Nm with a torque wrench.

Attention: If there is little difference in individual tire wear, fit the wheels with the least radial play and the least imbalance on the front axle.

Carry out a test drive. If vibrations are still present at the front of the vehicle or the steering wheel, this may be due to residual imbalance, which is corrected by subsequent balancing on the vehicle.

Subsequent balancing or wheel balancing on the vehicle

When balancing the drive wheels, be sure to rotate both tires of one axle.

The wheels must be driven by the vehicle's engine so that the wheels rotate synchronously.

Carry out a test drive.

If the faults still occur, then the radial or lateral runout of one or more tires is too high. It is impossible to measure this with SRT tools. In this case, it remains only to replace the front and / or rear tires. In this case, it is necessary to replace the tires in pairs, that is, for the entire bridge at the same time.

Visitor comments