Carburetor Weber 2V-ISC

Since idle speed is controlled by a stepper motor, no manual adjustment is required. If the idle speed does not correspond to the prescribed value, then the fault should be searched using the troubleshooting program (at the service station).

Attention: The deviation of the CO content by±0.20% is considered normal. Prerequisite for testing: The exhaust system must be tested. To do this, with the engine running, cover the exhaust pipe with a rag. All pipe connections must be tight.

Attention: When carrying out the check, make sure that the workplace is sufficiently ventilated. If this is not done, there is a risk of exhaust gas poisoning.

Check the carburetor rods and rollers for gaps. Repair and adjust the carburetor if necessary (service station work).

Warm up the engine and turn off. The lower coolant hose at the radiator should be warm.

Turn off all electrical consumers (radio, windshield wipers, etc.) and air conditioning system.

Check and, if necessary, adjust the ignition timing.

The air filter element must be clean. It is best to perform the adjustment after installing a new replacement air filter element.

In accordance with the operating instructions, connect devices for measuring the crankshaft speed and CO content. Screw on the air filter.

Note: On vehicles with a catalytic converter, the CO content is measured at the CO sampling pipe on the exhaust pipe.

Start the engine warmed up to operating temperature and leave it to idle.

Check the tightness of the intake tract. To do this, circle all the seals in the intake tract with a brush moistened with gasoline. If the crankshaft speed increases for a short time, then there is an additional air leak in the tract. Locate the leak and eliminate the cause.

Caution: Do not inhale gasoline vapors - they are poisonous! Avoid splashes of gasoline on hot parts and parts of the ignition system. Fire hazard!

Run the engine at 3000 rpm for about half a minute, then return to normal idle.

As soon as the readings of the measuring instruments have stabilized, read the measurement results and compare with the prescribed values, see p. 66.

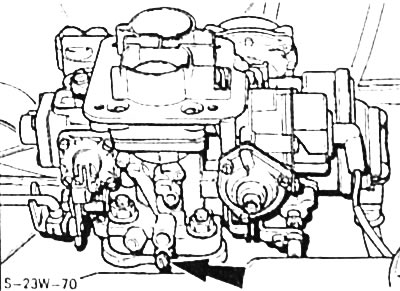

If the CO content deviates from the specified value, remove the protective cap from the adjusting screw -arrow-. To do this, drill a plastic cap in the center, screw a screw or sheet metal screw into the hole and, grabbing the screw with pliers, remove it together with the protective cap.

Run the engine at 3000 rpm for about half a minute, then return to normal idle.

Turn the adjusting screw -arrow- to set the CO content to the prescribed value.

Attention: Perform the adjustment within 30 seconds after the readings stabilize. Otherwise, make the engine run again at a crankshaft speed of 3000 1/min.

Recheck the idling speed and the CO content.

Install a new protective cap on the CO adjustment screw.

Remove gauges.

Visitor comments