Depending on the year of manufacture and equipment of the vehicle, electrical wires, as well as vacuum and coolant hoses, may be located in the engine compartment in different ways. Since it is impossible to dwell on each option individually, it is recommended to mark the corresponding wire with adhesive tape before removing it. Outlined below is the removal of a 4-cylinder DOHC engine built prior to 8/92.

Withdrawal

Disconnect ground wire (-) battery.

Caution: Disconnecting the battery will erase the contents of the electronic memories, such as engine trouble codes or radio codes. Before switching off, also read the instructions in chapter "Removing and installing the battery".

Remove the engine compartment hood see p. 132.

Remove the air filter together with the suction hose, see p. 57.

Drain engine oil, see section "Maintenance".

Vehicle with air conditioning system: remove V-belt, see p. 29.

Drain the coolant see p. 38.

Disconnect the upper and lower coolant hoses from the radiator, after releasing the fastening clamps.

Loosen the fastening clamps and disconnect all coolant hoses going to the expansion tank.

Loosen the fastening clamp and disconnect the heating hose from the coolant pump.

Depending on the engine: Disconnect the second heating hose at the cylinder head, at the intake manifold or at the cover of the automatic fuel mixture enrichment device at start-up. Loosen the clamp first.

V6 engine: unscrew the fastening of the fan impeller, see p. 41.

Unscrew the fastening and remove the radiator air guide shroud, see chapter "Removal and installation of a radiator".

V6 engine: remove the radiator, see p. 42.

Take off the throttle.

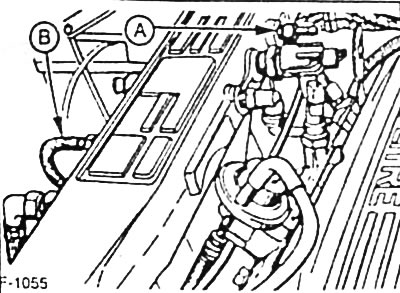

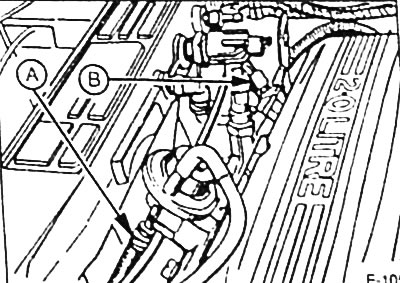

4-cylinder injection engine: Detach vacuum hoses from MAP sensor -A- and activated charcoal container -B-. To facilitate subsequent assembly, pre-mark the hoses with adhesive tape.

Carburetor engine: Disconnect the vacuum hose from the control unit.

If equipped, disconnect vacuum hoses from A/C compressor and automatic transmission.

Detach the breather hose at the cylinder head cover.

Injection engine: Loosen clamps and disconnect fuel hoses from pressure accumulator -A- and fuel lines -B-. Shake the connectors before disconnecting to prevent fuel splashing. Plug the fuel lines quickly with suitable plugs. To do this, insert, for example, clean threaded bolts of the appropriate diameter into the hoses. To facilitate subsequent assembly, pre-mark the hoses with adhesive tape. Attention: Carefully disconnect the fuel hoses so that the pressure in the fuel system can be relieved.

Release the clamps on the carburetor engine and disconnect the fuel hoses from the carburetor and from the fuel pump. Disconnect the plug-in connectors or unscrew the fastening of all electric cables going to the engine. To facilitate subsequent assembly, pre-mark the wires with adhesive tape.

- Generator multi-pin connector.

- Combination plug connector for fan motor.

- Plug connector for speed/crankshaft position sensor (CPS).

- Injection engine: Oxygen sensor connector.

- Engine with injection system, combo plug connector for engine management wiring harness.

- Injection engine: Combination plug connector for valve injectors.

- Carburetor engine: plug connector for automatic start-up enrichment device.

- Carburetor engine: intake manifold heating element connector.

- Carburetor motor combined plug connector of carburetor stepper motor.

- Plug connector for coolant temperature sensor

- Combined plug connector of the ignition distributor.

- Plug connector for coolant temperature switch.

- Plug connector for hydraulic switch.

Vehicle with power steering: Disconnect the pressure line and hose to the expansion tank at the power steering pump Place a container down and collect the fluid that flows out.

4-cylinder ONS engine: remove the engine oil level sensor from the crankcase.

Raise the car on the goats.

If equipped, remove the lower engine compartment cover.

Car with air conditioning

Attention. Do not open the refrigerant circuit of the air conditioning system. The refrigerant contains substances that can cause frostbite if it comes into contact with the skin. The engine can be removed without opening the refrigerant circuit.

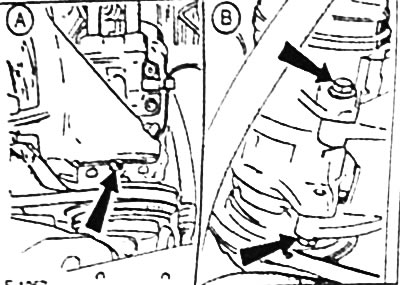

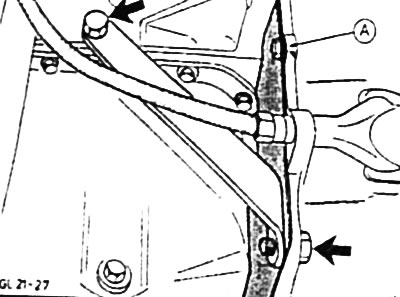

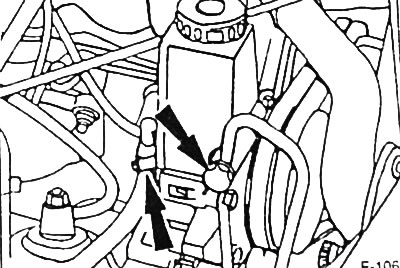

Unscrew securing bolts -arrows- and hang refrigerant compressor with connected hoses on a wire so that it does not interfere with further removal and hoses are not stretched.

Remove the front exhaust pipe from the exhaust manifold. Disconnect the exhaust system from all holders and removed, see p. 80.

Remove starter, see page 167.

Vehicles with automatic transmission: Remove 4 bolts -arrow- from torque converter through starter opening in clutch housing. To turn the engine crankshaft, put a ratchet mechanism with a suitable sprocket on its belt pulley.

Vehicles with manual transmission: unfasten the clutch drive rod or, respectively, disconnect the hydraulic drive from the gearbox, see p. 84.

V6 engine: remove oil filter, see p. 198.

4-cylinder OHO engine and V6 engine: Remove bolt -A- for engine intermediate plate.

4-cylinder ONS engine: Remove bolts -arrows- for gearbox brace.

Loosen all bolts securing the clutch housing flange. Disconnect ground wire, positive wire holder. and for a car with an automatic transmission, an oil filler tube, as well as a holder for the vacuum pipe.

Detach the brake pipes from the holders on the left and right at the front axle.

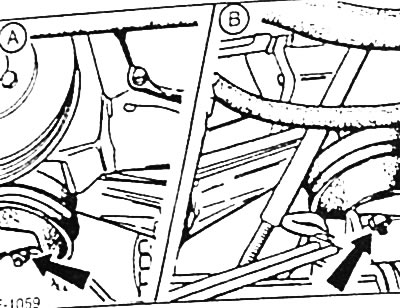

Remove nuts -arrows- for both engine mounts (A - right side of the engine B - left side of the engine).

Loosen locking pins -arrows- on left and right of coupling strut until the pins are still firmly seated in the thread of the side member.

Support the gearbox with a garage jack.

Check if all hoses and wires between engine and body are disconnected.

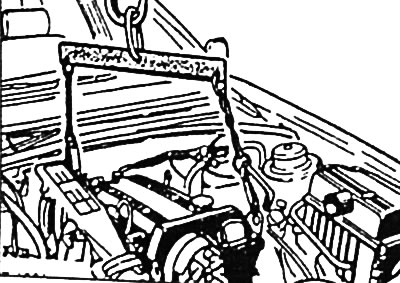

Insert the ends of the lifting device into the lugs for hanging the engine, it is easy to lift the engine with a crane and pull it forward. Disconnect the engine from the gearbox with a strong shaking motion. Lift the engine out of the engine compartment.

Installation

Check engine mounts, coolant, oil and fuel hoses for porosity and cracks, replace if necessary.

Check the ease of movement of the bearing and the clutch release lever, replace defective parts if necessary.

Check the thickness and condition of the clutch disc linings. Replace clutch disc if necessary.

Clean the splines of the gearbox input shaft and treat with MoS2 grease.

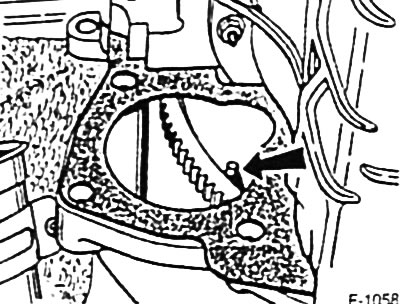

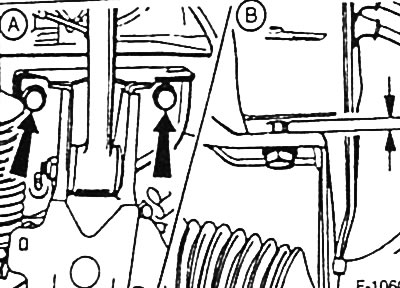

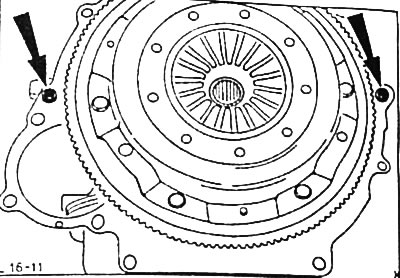

Check whether both guide bushes -arrows- are present in crankcase. If necessary, pull the guide bushings out of the clutch housing and drive them into the crankcase.

Put the intermediate plate on the guide bushings and glue it to the crankcase in several places with grease.

Attention: If there were intermediate plates in the area of the oil pan, then they must be installed as they were before removal.

Lower the engine into the engine compartment. When lowering, make sure that the drive shaft of the gearbox enters the pins of the clutch disc. If the shaft does not enter the splines of the clutch driven disk, use the ratchet mechanism to turn the engine crankshaft by the belt pulley.

With shaking movements, move the engine to the gearbox so that a gap of approximately 5 mm remains between their housings. Screw in 2 bolts until their heads touch the flange of the clutch housing.

Lower the engine completely, ensuring the correct position of its supports on the axle beam. Unfasten the engine jack.

Lower the garage jack under the gearbox and remove it.

Screw in all bolts securing the clutch housing flange. Connect the ground wire, the positive wire holder, or, on vehicles with automatic transmission, the oil filler tube, and the vacuum line holder.

Tighten the bolts securing the engine to the gearbox to 40 Nm.

4-cylinder ONS engine and V6 engine: Attach the engine intermediate plate and tighten the fastener to 10 Nm.

4-cylinder ONS engine: attach the gearbox tie and tighten the mounting bolts.

Vehicle with a manual transmission: attach the clutch drive rod or, respectively, connect the hydraulic drive to the gearbox, see p. 84.

Vehicles with automatic transmission: Insert the 4 converter mounting bolts through the starter hole in the clutch housing and tighten to 40 Nm.

Tighten the locking pins of the connecting column to 90 Nm.

Tighten the engine mounting nuts to 70 Nm.

Install the starter see p. 167.

Install the complete exhaust system see p. 80.

Vehicle with air conditioning system: Attach air conditioning compressor and tighten bolts to 75 Nm.

If equipped, install the lower engine compartment cover.

Lower the car.

Vehicle with power steering.

Connect the hose at the power steering pump to the expansion tank and secure it with a clamp.

Attach the pressure line to the power steering pump and tighten the fastener to 30 Nm.

4-cylinder ONS engine: Insert the engine oil level sensor into the crankcase.

Connect and secure all electrical wires and vacuum hoses as marked.

Install throttle.

V6 engine: install radiator, see p. 42.

V6 engine: install fan impeller, see p. 41.

Fit air guide shroud to radiator and tighten to 10 Nm.

Connect coolant hoses and secure with clamps

Connect the coolant hoses to the expansion tank and secure with clamps.

Connect the heating system hoses and secure with clamps.

Connect the inlet and outlet fuel hoses in accordance with the markings and secure them with clamps.

Connect the engine ventilation hose to the cylinder head

* Car with air conditioning system: install V-belt, see p. 29.

Install the air filter together with the suction hose, see p. 57.

V6 engine: install oil filter, see p. 198.

Pour engine oil into the engine see p. 198.

Vehicle with power steering, pour hydraulic fluid into the compensation tank of the hydraulic drive and remove air from the hydraulic drive, see p. 108.

Check the concentration of antifreeze in the coolant and fill it into the cooling system, see p. 200.

Install the engine compartment hood see p. 132.

Connect ground wire (-) battery.

If available, set the clock and enter the anti-theft code for the radio.

Check and, if necessary, adjust the ignition timing, see p. 50.

Carburetor engine: check and, if necessary, adjust the engine idling speed and CO content, see p. 64.

Warm up the engine to normal operating temperature, check the levels of working fluids and check the connections of all hoses for tightness.

Visitor comments