V-belt for alternator drive and power steering pump

ONS engine

Attention. The ONS engine is equipped with two V-belts. Both belts must always be replaced together.

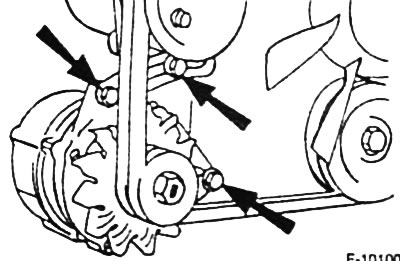

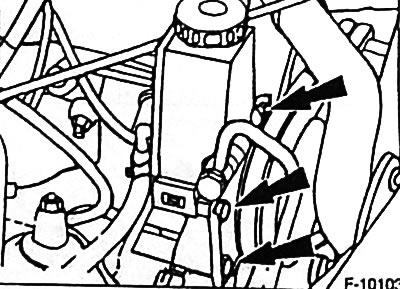

Loosen securing bolts -arrows-.

Tilt the alternator towards the engine and remove the V-belts.

Place new V-belts on the pulleys and, using a pry bar, press the alternator away from the engine, thus tensioning both V-belts.

Tighten the locking bolts to 25 Nm.

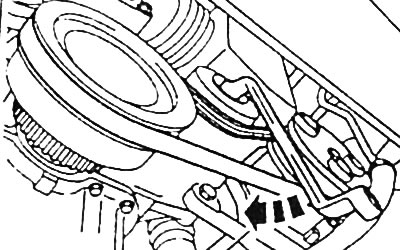

Vehicle without power steering: Check belt tension between coolant pump and alternator pulleys -arrow-. When pressed with the thumb, the belts should sag about 4 mm.

Vehicles with power steering: Check belt tension between coolant pump and power steering pump pulleys -arrow-. When pressed with the thumb, the belts should sag about 4 mm.

Popklinovy belt

DOHC engines with a displacement of 2.0 and 2.9 liters

DOHC engines are equipped with a V-ribbed belt, which simultaneously drives all auxiliary units. Depending on the equipment, the belt is tensioned automatically by the tensioning roller.

When applying the V-ribbed belt, make sure that it is correctly positioned on all pulleys.

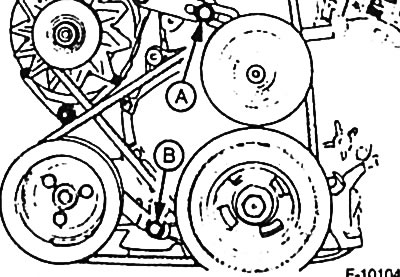

Models without idler (some models up to 8/94)

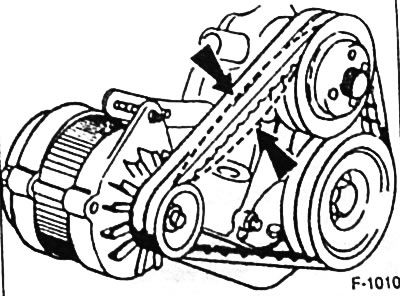

Loosen alternator retaining bolts -A-.

Tilt the alternator towards the engine and remove the V-ribbed belt.

Place a new V-ribbed belt on the pulleys and, using a pry bar, press the alternator away from the engine, thereby tensioning the V-ribbed belt.

Tighten the locking bolts to 25 Nm.

Idler pulley models

On models with a self-adjusting tensioner, the tension of the V-ribbed belt does not need to be adjusted. The condition of the V-ribbed belt should only be checked as part of regular maintenance, if necessary, the V-ribbed belt must be replaced.

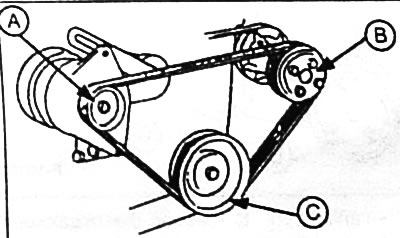

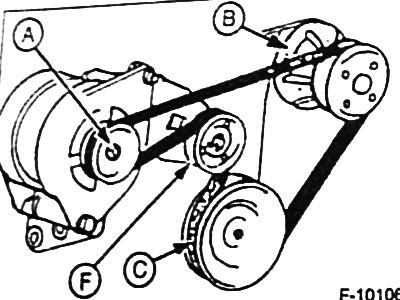

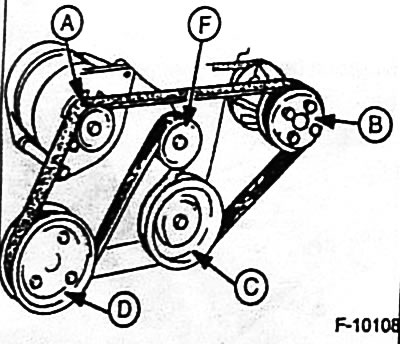

V-ribbed belt overlay scheme

2.0L DOHC Engine without Power Steering

2.0L displacement DOHC engine in a power steering vehicle (and/or air conditioning system)

A - generator; B - coolant pump; C - crankshaft belt pulley; D - hydraulic booster pump; F - self-adjusting tension roller.

Note: if there is an air conditioning compressor, it is located in the area between the crankshaft and the coolant pump.

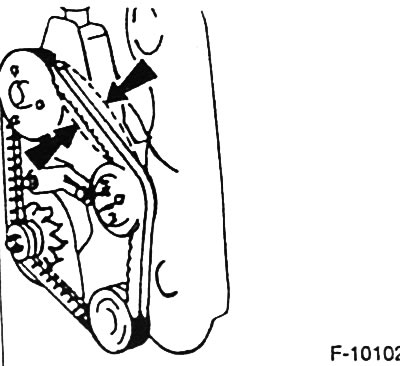

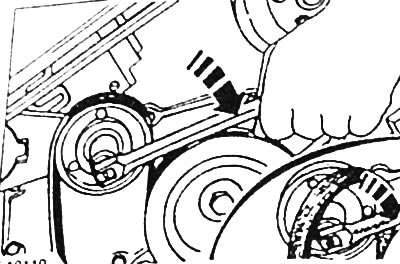

Using a sprocket and a wrench, loosen the belt tension by pressing the tension roller in the direction of the arrow and remove the V-ribbed belt.

V6-DOHC engine from 9/94: Turn tensioning pulley for separate V-ribbed belt to the right.

To apply the V-ribbed belt, press the tensioning roller in the direction of the arrow.

V-belts for alternator drive and power steering pump

V6-OHC engine up to 8/94

Release locking and adjusting bots.

Remove V-belts.

Place new V-belts on the pulleys and, using a pry bar, press the alternator away from the engine, thus tensioning both V-belts.

Attention: Do not press on the expansion tank.

Tighten locking and adjusting bolts to 55 Nm.

Check belt tension between coolant pump and power steering pump pulleys. When pressed with the thumb, the belts should sag about 4 mm.

V-belt for driving the air conditioning compressor: Loosen the locking and fixing bolts.

Tilt the compressor towards the engine and remove the V-belts.

Place new V-belts on the pulleys and adjust the tension by turning the compressor.

Tighten the locking bolts to 25 Nm.

Check the tension of the belts in the area with the largest distance between the pulleys. When pressed with the thumb, each belt should sag about 4 mm.

Tighten locking and fixing bolts to 75 Nm.

V-belts for alternator drive and power steering pump

Naturally aspirated and turbocharged diesel engines up to 8/93

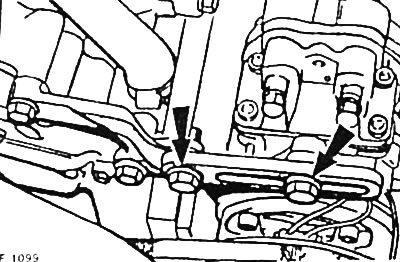

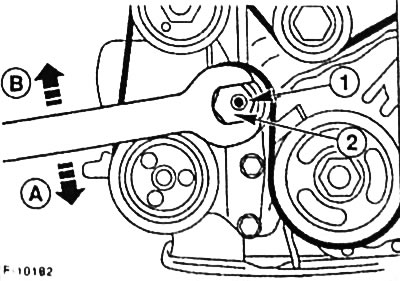

Loosen securing bolts and tensioning bolt -B- for power steering pump.

Remove the V-belt for driving the power steering pump.

Loosen the mounting bolts and tensioning bolt -A- of the alternator.

Remove the V-belt to drive the alternator.

Fit new V-belt.

Using a pry bar, press the alternator away from the engine and thereby tension the V-belt.

Tighten the mounting bolts and tension bolt to 25 Nm.

Using a pry bar, press the power steering pump away from the engine and thereby tension the V-belt.

Tighten the fastening bolts and the tension bolt to 95 Nm.

Check the tension of the belts in the area with the largest distance between the pulleys. When pressed with the thumb, each belt should sag by about 4 mm, otherwise repeat the tension adjustment.

V-ribbed belt for driving all auxiliary units

Turbo diesel engine from 8/93 to 8/94

Disconnect ground wire (-) battery.

Caution: Disconnecting the battery will erase the contents of electronic storage devices. for example, for engine trouble codes or radio code. Before switching off, also read the instructions in chapter "Removing and installing the battery".

Remove suction line. To do this, release the clamp and fastening clip, remove the ventilation system pipeline and pull the pipe out of the air filter.

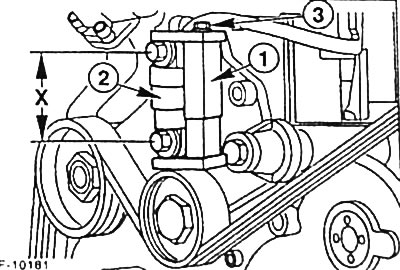

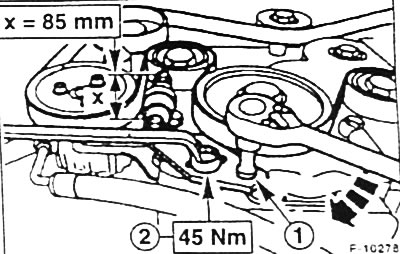

Place the special tool -1- FORD 91-180 on the automatic belt tensioner and turn the bolt -3- until dimension X = 80 mm is achieved.

Loosen bolt -1- for lower belt tensioner.

Attention: Left-hand thread, turn to the right to loosen.

Turn the adjusting eccentric -2- in the direction of the arrow -A- until the tension of the V-ribbed belt is completely released. In this position, tighten the fastening bolt to 45 Nm.

Remove poly V-belt.

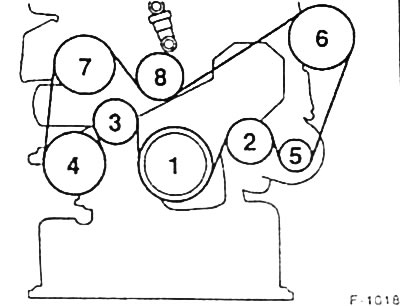

Place a new V-ribbed belt on the pulleys in ascending order of their numbering from 1 to 8.

Release and remove the special tool.

Install intake pipe.

Connect ground wire (-) battery.

Start the engine and let it idle for about 10 minutes.

Disconnect ground wire (-) battery, remove the intake manifold.

Loosen the lower belt tensioner bolt.

Note: Left hand thread.

Turn the adjusting eccentric clockwise -B- until the dimension X = 81-83 mm is achieved at the automatic belt tensioner. In this position, tighten the fastening bolt to 45 Nm.

Install intake pipe.

Connect ground wire (-) battery. Set the clock, enter the radio anti-theft code.

V-ribbed belt for driving all auxiliary units

Turbo diesel engine from 9/94

Put the car in front on the goats.

Install socket wrench -1- on automatic belt tensioner and loosen bolt -9-. Turn the socket wrench to the left and remove the belt.

Apply new belt in sequence. shown in Figure F-10183.

Turn the automatic belt tensioner clockwise until dimension X = 85 mm is reached (from the center of one bolt to the center of another bolt). In this position tighten bolt -9- to 45 Nm.

Attention: Start the engine, leave it to idle for about 5 minutes, then check the size again. Adjust the position of the belt tensioner if necessary.

Lower the car.

Visitor comments