ONS engine

To check the tension of the toothed belt, a FORD 21-113 tester is required. Incorrect toothed belt tension causes noise during operation and leads to intense belt wear.

Withdrawal

Shift the transmission to neutral, apply the handbrake.

Remove the V-belt see p. 29.

Remove the ignition distributor cap, see p. 47.

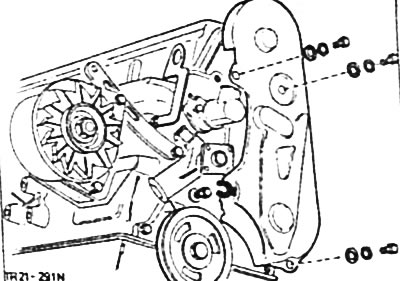

Unscrew fastening of the toothed belt guard and pull the guard from the side together with the guide clips from the retaining pins. Tilt the casing from below, then remove it from the camshaft gear (for clarity, the fan is not shown in the figure).

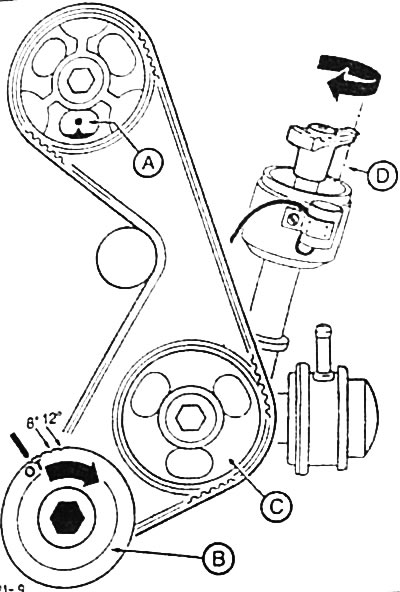

Place the engine crankshaft in a position where the piston of cylinder 1 is in the BMT of the combustion process. To do this, turn the crankshaft so. so that the mark on the crankcase matches the mark on the crankshaft gear, see figure GL21-9 below.

At the same time, the mark on the camshaft sprocket must align with the alignment mark on the cylinder head. If this does not happen, then the crankshaft must be rotated another 360° (for a full turn) in the direction of its rotation.

The crankshaft is rotated by a gear mounted on the shaft using a socket head and a wrench.

Attention: Do not turn the engine shaft by the camshaft gear, as the toothed belt is subjected to a very strong load.

After the marks match, do not change the engine adjustment in any case.

If a used belt is to be used again, mark the direction of travel before removing it. To do this, an arrow is applied to the belt using a felt-tip pen or marker in the direction of rotation of the motor shaft. The direction of rotation of the crankshaft is shown in figure GL 21-9 below.

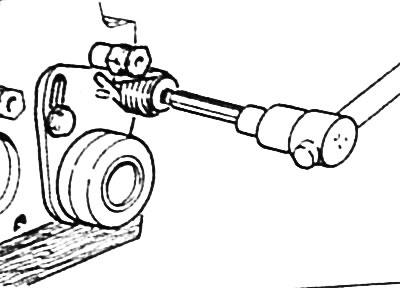

Loosen toothed belt tension. To do this, at the belt tensioner, first release the bolt with internal pins in the head, and then the hex bolt. After that, press the belt tensioner against the action of the tension spring and tighten the bolts of its fastening again.

Attention: To loosen the hex head bolt, a heavily curved 13mm ring wrench is required. Otherwise, you need to drain some of the coolant and remove the thermostat housing.

Loosen the crankshaft pulley and remove the thrust washer. To do this, engage 5th gear and apply the handbrake. If the toothed belt is only to be removed from the camshaft sprocket, then the belt pulley does not need to be removed.

Caution: The crankshaft must not turn when the belt pulley is released.

Remove the toothed belt and then do not change the position of the gear wheels.

Installation

Caution: Do not break or twist the toothed belt. Filthy. Replace damaged or worn toothed belt in any case. Check the tension roller for uniformity and ease of movement.

Attention. If the camshaft is to be rotated with the camshaft removed, no pistons should be in the TDC position. Otherwise, pistons and valves may be seriously damaged.

If the camshaft must be rotated, then all pistons must first be set to the position corresponding to half their stroke. To do this, put a line with chalk on the top of the crankshaft wheel (prerequisite: the crankshaft is in the position where the piston of cylinder 1 is at TDC), then turn the crankshaft to the right or left 1/4 turn. The chalk line should now be horizontal on the wheel to the right or left.

Make sure that the position of the camshaft sprocket -A- corresponds to the TDC position of the piston of cylinder 1. The mark on the camshaft sprocket must match the alignment mark on the cylinder head.

At the same time, the marks on the crankshaft sprocket -B- and crankcase must match. In this case, the piston of cylinder 1 will be at TDC of the combustion process.

Turn the countershaft sprocket -C- so that the mark on the tongue of the distributor rotor is above the mark on the edge of the distributor housing.

Place the toothed belt on the gear wheels in accordance with figure GL 21-9. Make sure that the pulling side of the belt (She is on the right in the picture) was very tight. If a used belt is installed, then it should be applied in accordance with the arrow applied before removal, showing the direction of movement of the belt.

Attention: When applying the toothed belt, neither the crankshaft nor the camshaft must change their position. Otherwise, the engine may be severely damaged or may not be able to develop full power.

Attach the belt pulley with thrust washer to the crankshaft and tighten the mounting bolts to 120 Nm.

Loosen the tensioner pulley mounting bolts so that it can rest on the toothed belt.

Tighten the tensioning roller bolts to 25 Nm: first tighten the hexagon bolt and then the slotted bolt.

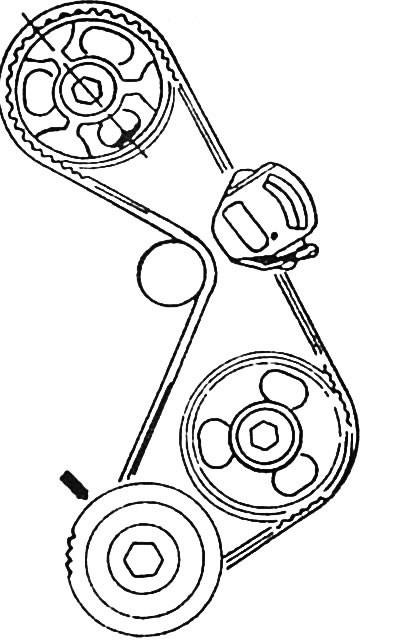

Rotate crankshaft 2 turns in direction of rotation and check adjustment. The marks on the camshaft sprocket, the crankshaft sprocket and on the ignition distributor rotor must line up with their alignment marks.

Turn the crankshaft against the direction of rotation by approx. 60°. This corresponds to approximately three camshaft gear tooth pitches.

Check the tension of the toothed belt using the FORD 21-113 tester. Attach the tool to the belt in the middle between the gears of the camshaft and intermediate shaft. The gauge should show 4-5 units for a used belt or 10-11 units for a new belt. If the specified value is not reached, turn the engine crankshaft again to the position where the piston of cylinder 1 is at TDC of the combustion process. Release the tension roller mounting bolts and turn the roller accordingly. After that, tighten the tensioning roller mounting bolts to 25 Nm.

Rotate crankshaft 2 turns in direction of rotation and recheck toothed belt tension.

Install toothed belt guard and secure with three bolts.

Install the ignition distributor cap, see p. 47.

Install the V-belt see p. 29.

Check and, if necessary, adjust the ignition timing, see p. 50.

Visitor comments