Withdrawal

Apply the handbrake and shift the transmission into neutral.

Remove spark plug caps and remove spark plugs.

ONS engine: remove the push lever, see p. 22.

DONS engine: remove camshafts and poppets, see p. 16.

V6-OHV engine: remove rocker shafts, see p. 19.

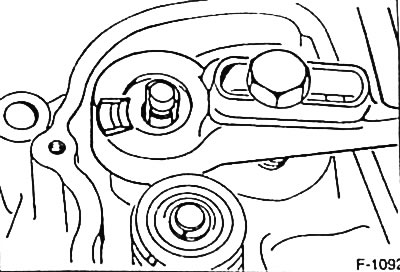

Screw the HAZET 3428 adapter with the compressed air hose connected into the threaded hole for the spark plug of the corresponding cylinder.

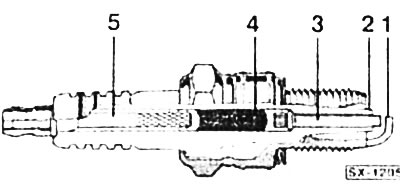

If there is no adapter. it can be made from an old spark plug. To do this, remove the earth electrode -1-. Use a screwdriver to destroy the ceramic insulator -2-, then, swinging the central electrode -3- in different directions, break it off and pull it out. Knock out the rest of the central electrode together with fiberglass -4- and the connecting electrode -5- with a suitable drift (about 3 mm in diameter). In this case, clamp the spark plug in a vise or insert it into a suitable socket head.

Attention: To avoid damage to the threads in the cylinder head. spark plug thread must not be damaged.

Screw the prepared spark plug into the appropriate cylinder and connect it to the compressed air hose.

Continuously pressurize the cylinder with compressed air at a pressure of at least 6 bar.

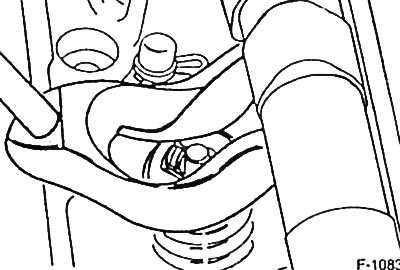

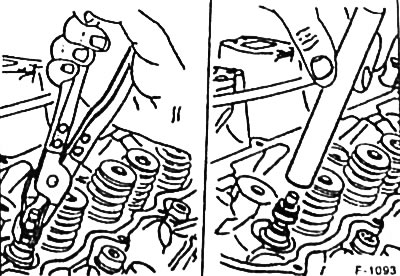

ONS engine: Using the FORD 21-005B tool, press the valve spring plate down and remove the crackers from the valve recess.

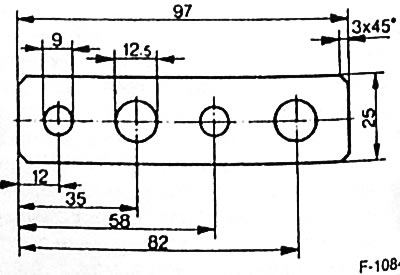

4-cylinder DOHC engine

In accordance with the figure, make a retaining plate from a steel sheet 6 mm thick.

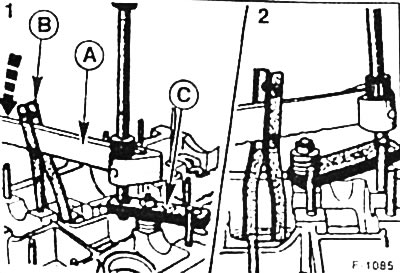

Make your own retaining plate -C- and, as shown in the figure, screw it with a nut on the stud securing the camshaft bearing cover. Attach special tool FORD 212-024 -A- and 21-024-04 -B-. compress the valve spring with it and remove crackers from the valve stem.

V6 OHV engine: compress the valve springs with the FORD 21-056 special tool and remove the crackers from the valve stem.

Caution: When pressing the spring plate to remove the cotters, do not damage the valve stem. If the stem is damaged, the valve must be replaced, as a damaged rod wears out quickly.

Release the valve springs, remove the upper and lower spring plates and valve springs.

Remove the oil seal. In the workshop, removal is carried out using standard tools such as GV 2124, HAZET 791-5 or HAZET 791-2 impact puller. Old valve stem seals are usually very tight. Therefore, if possible, use an impact extractor to remove them.

Attention: Remove valve stem seals carefully so as not to damage their seats

Installation

In order not to damage the valve stem seals, glue the undercut for crackers in the valve stem with adhesive tape.

Push a new lubricated valve stem seal onto the valve guide by hand.

Use a hammer and a FORD special tool to upset the valve stem seal. If a special tool is not available, you can use a suitable tube without sharp edges, having the same diameter as the valve stem seals. Special tool FORD - for engine ONS 21-007; for DOHC and V6 engines: 21-130A

Remove adhesive film.

Insert the lower and upper spring plates together with the springs and compress the springs.

Insert crackers and release springs.

Replace other valve stem seals in the same way.

V6 OHV engine: install rocker axles, see p. 19.

4-cylinder DOHC engine: install camshafts and poppets, see p. 16.

ONS engine: install push levers, see p. 22.

Install the cylinder head cover see p. 16.

Visitor comments