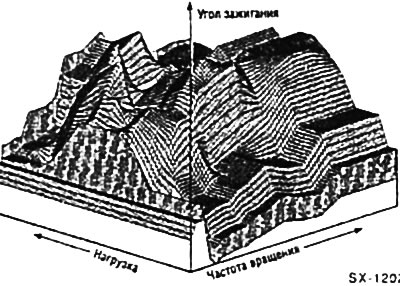

The optimal ignition timing depends primarily on the instantaneous values of the crankshaft speed and engine load. The instantaneous engine load is determined by the control unit based on the ratio of the crankshaft speed and the vacuum in the intake manifold or, respectively, the position of the throttle valve. Based on the characteristics of the ignition timing entered in the electronic memory, the control unit calculates the desired ignition timing.

For a carburetor engine, an additional change in the ignition timing is carried out using a centrifugal control mechanism and vacuum (a vacuum hose connects the ignition distributor to the intake manifold). On the engine with Weber 2V-ISC carburetor, the ESC-H control unit additionally regulates the idling speed by means of a stepper motor at the carburetor.

The ignition distributor is equipped with a maintenance-free Hall sensor. The Hall sensor consists of a non-contact permanent magnet and a distributor mounted on the shaft and a screen rotating with it. Through the control unit, the Hall sensor determines the time for the ignition system to turn off and turn on the current through the ignition coil and thereby sets the ignition timing.

Distributionless ignition system

DOHC 2.0-/2.3L engines since 9/94 and V6 DOHC

The function of distributing high voltage to the spark plugs of individual cylinders is performed by fixed electronically controlled parts, which replaced the conventional mechanical distributor with a rotating rotor.

The ignition system has 2 or 3 ignition coils, respectively, which are mounted in the area of the spark plugs. Synchronization of the ignition system is carried out using signals transmitted to the control unit of the pulse encoder. The pulse encoder is located on the side of the cylinder head and registers the camshaft speed. The ignition system control unit is located at the end of the crankcase next to the expansion tank of the cooling system.

The injection and ignition systems have a common electronic control unit, which is equipped with a fault code memory. It accumulates fault codes that occur in the engine electronics when traveling. Before repairing the ignition system, it is first of all necessary to interrogate the memory device. Interrogation of the storage device is carried out using a diagnostic tool through the diagnostic connector located behind the cover on the left in the driver's footwell.

Since the motorist, as a rule, does not have a diagnostic tool, it is recommended to print out the contents of the fault code memory at the service station.

Visitor comments