Withdrawal

Remove gearbox.

Models up to 8/94: Detach the clutch release bearing at the top and bottom of the fork and remove it from the transmission input shaft.

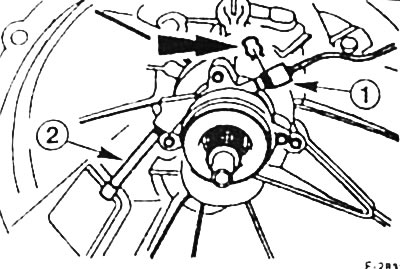

Models from 9/94: Remove retaining spring -arrow- at slave cylinder, disconnect quick coupling -1-. Unscrew bleeder valve -2-. Unscrew the 3 bolts securing the slave cylinder to the gearbox and remove it together with the clutch release bearing from the gearbox input shaft.

Examination

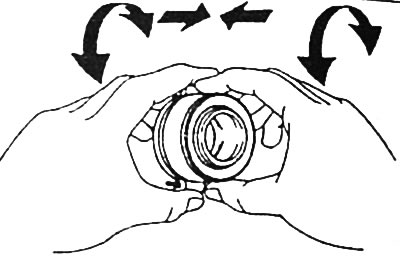

Compress the parts of the clutch release bearing and simultaneously turn in different directions. If the bearing has play, it must be replaced with a new one.

Attention: The bearing is filled with grease for life and must not be cleaned or replenished with grease.

Check bearing contact surfaces for wear, corrosion and damage.

Installation

Apply a thin coat of high temperature grease such as MoS2 to all clutch release bearing surfaces and contact surfaces. If necessary, remove the remains of the old hardened grease.

Attention: Do not apply too much lubricant, so that when the clutch is installed, it does not get on the working surfaces of the discs.

Models up to 8/94: insert the clutch release bearing and attach it to the fork.

Models from 9/94: Tighten the slave cylinder with clutch release bearing to the gearbox to 10 Nm. Connect the quick coupling at the slave cylinder and insert the retaining spring, see figure F-2B32 above. Close the air bleed valve. After installing the gearbox, bleed the air from the clutch hydraulic drive.

Install the gearbox see p. 90.

Visitor comments