Needle valve

Since May 1983 (production date code "DL") a new type of needle valve has been introduced that controls the fuel supply to the float chamber, as well as a new needle valve clamp.

In the event of repeated engine stops immediately after starting it, remove the carburetor cover and, if there is no fuel in the float chamber, proceed as follows.

1. Remove float shaft and needle valve clamp (if present in this type), making sure that both of these elements do not fall inside the float chamber.

2. Remove needle valve (not re-installable).

Attention! Do not unscrew the fastening bolts of the fuel metering elements in order to facilitate access to the float.

3. Install the new needle valve and the new clip, making sure that the clip is properly seated in its groove in the valve.

4. Insert the float, paying attention to the correct position of the spacer between the lever holder and the needle valve, and insert the shaft into the cutout of the float holder.

5. Move the float several times, checking the possibility of its free rotation on the axis.

6. Install a new float chamber cover gasket and tighten the carburetor cover bolts to 2.5 Nm.

Attention! Variable throat carburetors were not initially equipped with a needle valve clamp.

Throttle control

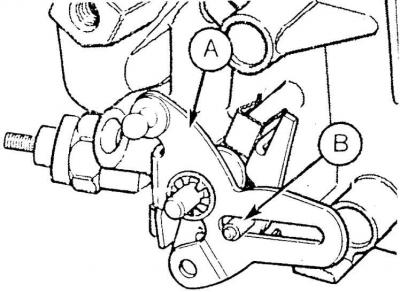

Ford Carburetor Throttle Lever

A - throttle lever

B - a rod made of artificial material

Since January 1985 (production date code "FJ") changed lever (A) throttle, rod (IN) from artificial material. In case of malfunction of the old type throttle control mechanism caused by rod wear (IN) made of artificial material, a new type of lever and rod should be installed.

Attention! There are two types of throttle levers - straight or curved. Be sure to use a lever with a cutout of the same shape as in the factory.

Visitor comments