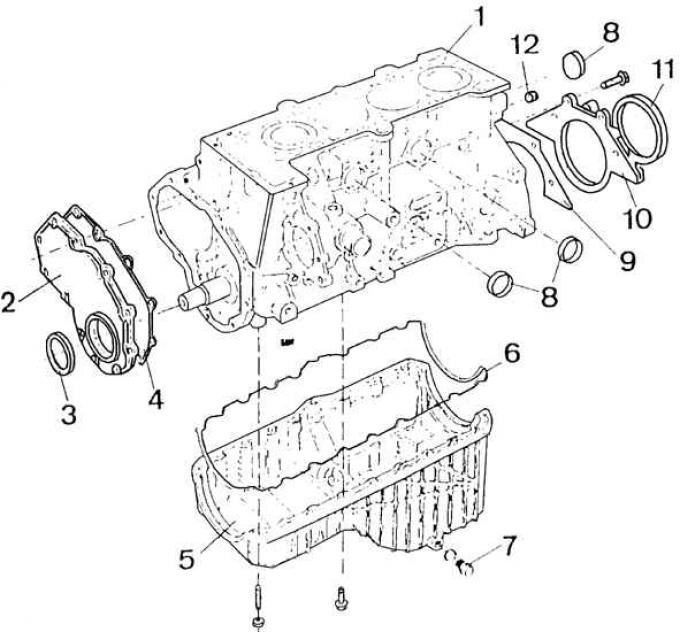

DOHC engine block

1 - cylinder block, 2 - cylinder block front cover, 3 - crankshaft front O-ring, 4 - cylinder block front cover gasket, 5 - oil pan, 6 - oil pan gasket, 7 - oil drain plug, 8 - plugs, 9 - gasket of the rear cover of the cylinder block, 10 - rear cover of the cylinder block, 11 - rear crankshaft sealing ring, 12 - threaded plug

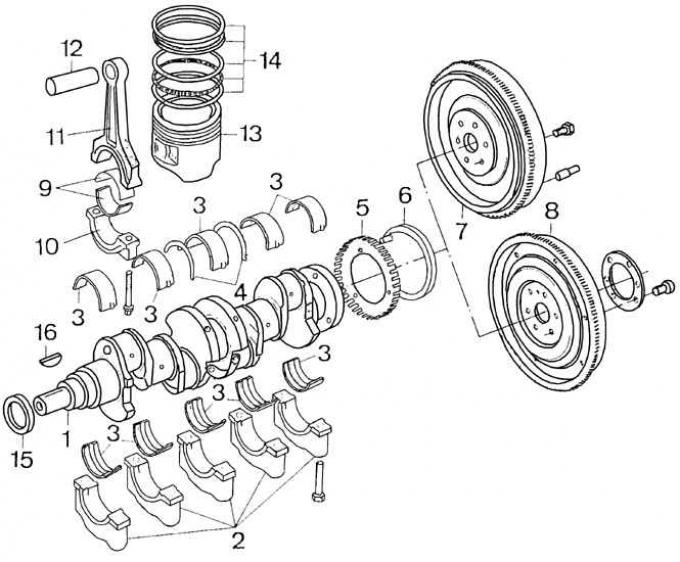

DOHC engine crank mechanism

1 - crankshaft, 2 - main bearing caps, 3 - main bearing shells, 4 - crankshaft thrust washers, 5 - crankshaft position sensor ring gear, 6 - crankshaft rear O-ring, 7 - engine flywheel with manual transmission, 8 - flywheel of a car engine with an automatic transmission, 9 - connecting rod bearings, 10 - connecting rod cover, 11 - connecting rod, 12 - piston pin, 13 - piston, 14 - piston rings, 15 - front sealing ring of the crankshaft, 16 - segmental key

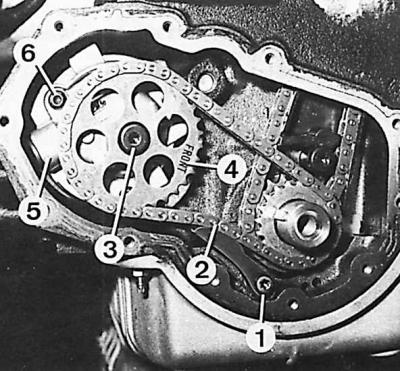

Removing the DOHC engine oil pump

1 - chain tensioner, 2 - pump drive chain, 3 - pump sprocket bolt, 4 - pump sprocket, 5 - oil pump, 6 - oil pump bolt to cylinder block

Disassembly

1. Mount the motor on a suitable frame.

2. Drain the engine oil and remove the oil level indicator.

3. Unscrew the oil filter using a suitable tool.

4. Unscrew the bolts securing the leading part of the clutch, and then remove the clutch disc.

5. Remove flywheel.

6. Remove the alternator drive and coolant pump V-belt, alternator and its holder.

7. Remove the crankshaft vibration damper using a suitable puller.

8. Remove the distributor cap and unscrew the spark plugs.

9. Remove the ignition distributor and unscrew the holder for high voltage wires.

10. Remove the cylinder head cover.

11. Remove the upper and lower covers of the universal joint chain of the gas distribution system.

12. Remove the oil pump propeller chain tensioner.

13. Unscrew the oil pump sprocket bolts and remove it together with the chain.

14. Disconnect the upper propeller chain guide of the gas distribution system.

15. Unscrew the two bolts securing the side guide of the propeller chain of the gas distribution system.

16. Remove the spring clamp securing the axis of the tensioner of the propeller chain of the gas distribution system.

17. Remove the axis of the tensioner of the cardan chain of the gas distribution system. with M6x70 bolt and 15 mm long sleeve (see fig. DOHC Engine Timing Installation).

18. Remove the chain tensioner lever.

19. Remove sprockets from camshafts.

20. Remove the top chain guide (up).

21. Remove the double sprocket from the crankshaft.

22. Remove the camshaft drive chain.

23. Remove the chain tensioner pusher.

24. Remove two camshafts (cap designation: "R" - intake valve shaft "L" - exhaust valve shaft, numbers "1" – "5" - bearing number, counting from the drive side of the gas distribution system).

25. Remove the hydraulic valve lifters and mark them in such a way that during the assembly process they can be installed in the guides with which they interacted.

Attention! Magnets must not be used when extracting tappets from the guides, as they may cause the valve inside the tappet to malfunction.

26. Remove the rigid bleed lines under the cylinder head cover.

27. Unscrew the cylinder head bolts, first unscrewing the three front M8 bolts, and then the M11 bolts in the reverse order with respect to their screwing (see fig. DOHC cylinder head bolt tightening sequence), initially loosening them by half a turn.

28. Remove the oil pump Torx bolts and remove the oil pump.

29. Unscrew the oil pressure sensor and the crankshaft position sensor.

30. Remove the oil pan after unscrewing its fastening bolts.

31. Remove the oil pump strainer and oil pan baffle (oil deflector).

32. Remove the front and rear crankshaft O-rings.

33. Check the designations of the main bearing caps, unscrew the bolts of their fastening and remove the caps together with their liners.

34. Remove crankshaft. Be careful not to damage the gear pulse sensor that interacts with the crankshaft position sensor.

35. Remove the crankshaft thrust half-ring and the main bearing shells from the cylinder block from the middle bearing and mark them accordingly.

Visitor comments