The location of the fuse links on your specific vehicle can be determined from the wiring diagram at the end of this chapter.

Fusible connecting links are not repairable. When replacing a link, make sure the new one is exactly the same gauge, length, and insulation.

Warning: Do not confuse fusible link and resistance. The resistance wire is usually longer and is labeled with a warning "Resister - don't cut or splice" "Resistance - do not cut or splice".

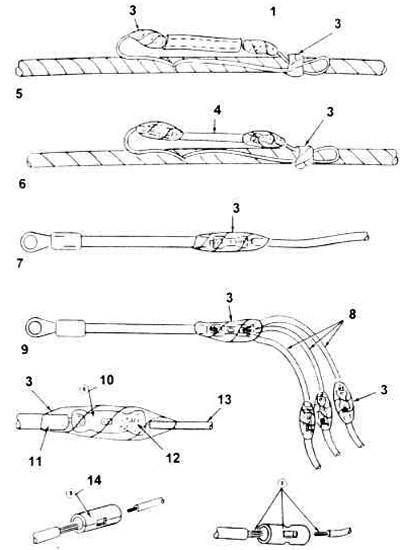

Fused connecting links of the charging system

1. Replacing the fusible link of the charging system is carried out as follows:

- A) Disconnect the wire from the negative battery terminal.

- b) Disconnect the fusible link from the wire, or disconnect the lug of the fusible link contact from the battery terminal of the starter relay (in some vehicles, the fusible connector is a loop on the outside of the wire bundle).

- V) Cut the damaged link from the wires to which it is connected.

- G) Solder the new fusible link to the wires from which the old one was cut.

- d) Carefully wrap the connection points with insulation.

- e) Connect the lug of the contact terminal securely to the battery stud on the starter relay.

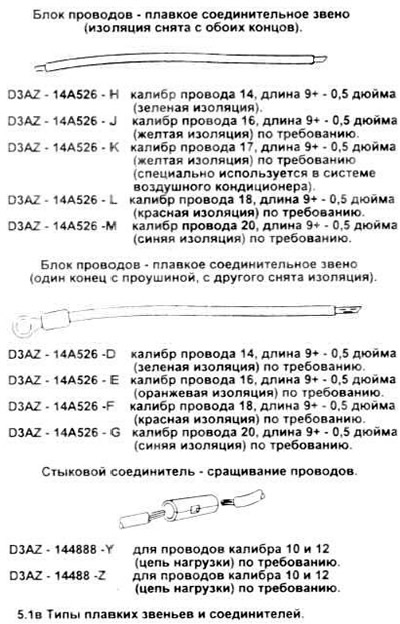

Note: some fusible links (see picture) have a terminal eye at one end for a 5/16" stud. In cases where no contact is necessary, use one of the fusible links shown with the insulator removed from both ends.

- and) Install the wires like this. as they were before.

- h) Connect the negative battery cable.

- And) Check circuit operation.

5.1, b. Details for the repair of fusible connecting links.

1. Remove the existing tubular vinyl screen.

2. Before crimping the fusible link to the ends of the wires, reinstall it over the fusible link.

3. Insulating tape.

5. Repair using 17 gauge (9 inches long - yellow), fuse link for air conditioner circuits (2) 687 E and 261 A, located in the engine compartment.

4. Fuse link.

6. Repair option for any internal fusible link - a different link gauge is used for each chain.

7. Repair option using a fusible link of a certain caliber with a contact - an eye.

8. Three fusible links.

9. Option to repair the connection of three easily fusible links to one powerful caliber supply wire.

10. D3AZ - 14488 - Y butt connector for 10-12 gauge wires.

11. 10-12 gauge wire.

12. Double wire crimp.

13. Light gauge wire.

14. D3AZ - 14488 - Y butt connector for 14-16 gauge wires.

All other fusible connecting links

2. For all other burnt fusible links, follow these procedures.

- A) determine the damaged circuit, its location and the cause of the broken fuse link.

- b) disconnect the negative battery cable.

- V) cut out the damaged fusible link and discard it.

- G) determine the correct fusible link, make sure the link is connected to the wiring correctly

- d) use connectors and wires in the right places, insulate with electrical tape.

4. To replace the fuse link of a separate circuit in a wire bundle. cut out the damaged area, strip the wire at both ends about 1/2 inch of insulation, and use two appropriately sized butt connectors to connect the replacement fuse link to the bare circuit wires. Insulate connectors and wires with electrical tape.

5. When working with a fusible link that has an eye on one of the ends (as in the charging circuit), cut the burnt fusible link behind the solder spot, strip the wire 12.7mm (1/2 inch) from the cut end and connect a suitable new lug fusible link to the stripped end of the wire with a butt connector and insulate with tape.

6. Connect the wire to the negative terminal of the battery.

7. Check system operation.

Visitor comments