General description

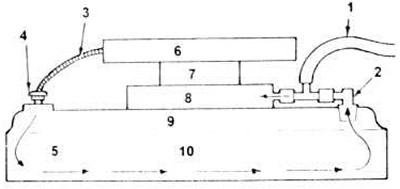

1. Efficient crankcase ventilation system (PCV) (see picture). drives crankcase vapors back to the engine where they are burned. The valve regulates the amount of ventilated air and purge gas into the intake manifold and prevents burning particles from entering the crankcase.

6.1. Typical effective crankcase ventilation system.

1. To the valve - evaporator.

2. PCV valve.

3. Sealed hose for 2.3L and 3.8L engines.

4. Oil filler cap.

5. Air way.

6. Air cleaner.

7. Carburetor.

8. Intake manifold.

9. Timing cover.

10. Engine crankcase.

2. PCV system consists of replaceable PCV valve, crankcase ventilation filter (on some vehicles it is integral with the oil filler cap, on others it is separate) and connecting hoses.

3. The air source for the crankcase ventilation system is the air cleaner. Air passes through the PCV filter (in the timing gear cover or oil filler cap) and through a hose connected to the air cleaner housing. Where the PCV filter is mounted in the oil filler cap, the cap is contoured to prevent outside air from entering. From the oil filler cap, or alternatively from a separate PCV filter on the timing cover, air enters the timing chamber and crankcase, from where it circulates up into another section of the timing chamber and finally reaches the spring-loaded valve adjuster (PCV valve), which changes the flow rate according to changing conditions. Vapors enter the intake manifold through the crankcase vent hose tube and nozzles. This process goes on continuously with the engine running.

Examination

4. A description of the procedures for checking the elements of the PCV system is included in chapter 1.

Replacing elements

5. Replacing elements consists of simply installing a new valve or hose in place of the one removed during the inspection process.

Visitor comments