2. Before honing the cylinders, install the main bearing caps and tighten the bolts to the correct torque.

3. Usually use one of two hone - flexible type "bottle brush" or the more famous spring-loaded sanding stones. You will also need plenty of light or honing oil, a rag, an electric drill.

Proceed as follows:

A) install hone in the drill, tighten the grinding bars and put it into the hole of the first cylinder (see picture).

Caution: Wear safety goggles or a face shield.

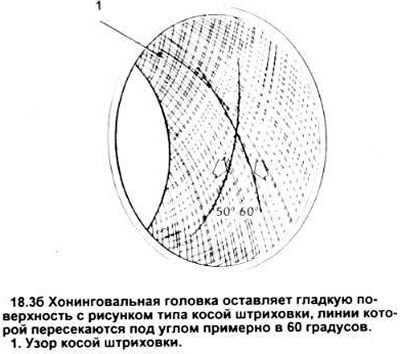

b) generously lubricate the hole with oil, turn on the drill and move the hone up and down in the cylinder along such a path that its walls are honed at an angle. Ideally, the machining marks should intersect each other at an angle of approximately 60 degrees (see picture). (Be sure to generously lubricate the cylinder surface and do not remove any more metal than is absolutely necessary for this treatment.

Note: be sure to read the instructions that come with new rings - manufacturers may recommend a smaller trace intersection angle than 60 degrees.

V) while the hone is on, do not remove it from the cylinder bore. Turn off the drill, keep moving the hone up and down inside the hole until it stops rotating completely, then tighten the bars and remove it. If you have a hone type "bottle brush", then turning off the drill, remove the hone from the hole, slightly turning the cartridge in the direction of rotation.

G) remove the oil from the treated cylinder and repeat the procedure with the remaining cylinders.

4. After honing, make small chamfers with a file along the edges of the cylinder bores so that the rings do not pinch when installing the pistons.

Caution: Do not damage the cylinder walls with the end of the file.

5. After honing, the entire block must be re-washed with warm, soapy water to remove metal chips and abrasive.

Note: the holes can be considered clean if a white cloth moistened with pure oil is passed inside, and there will be no traces of abrasive or metal chips on it (in the form of gray spots on the fabric).

Go through all channels and openings with a brush, then rinse them with running water.

6. After rinsing, dry the block and apply a coat of light anti-rust oil to the work surfaces. Wrap the block in a plastic bag (clean), so that it doesn't get dirty.

Visitor comments