Note: The crankshaft can only be removed with the engine removed from the vehicle. It is assumed that the flywheel or drive plate has already been removed vibration damper / crankshaft pulley hub, camshaft chain (for V6 engines), oil pan, oil pump and pistons complete with connecting rod. On a four-cylinder engine, before the crankshaft removal procedure, the housing seal must be unscrewed and separated from the block.

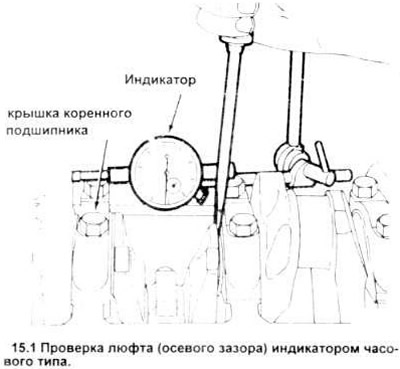

1. Before removing the crankshaft, check the play (axial clearance). To do this, install the dial indicator so that its leg is aligned with the crankshaft and touches one of the cranks (see picture).

2. Pushing the crankshaft to the right, reset the indicator to zero. Then use the lever to move the crankshaft forward as far as possible and take readings from the indicator. The distance it moves is the axial clearance. If it is more than acceptable, check if the axial surfaces of the crankshaft are worn out. If wear is not noticeable, the axial clearance can be corrected by replacing the main bearings.

3. If it is not possible to use the indicator, then you can use probes. Gently move the lever or push the crankshaft towards the front of the engine. Install a feeler gauge between the crankshaft and the front face of the main main bearing to determine the clearance (see picture).

4. Check the markings of the main bearing caps, this is necessary in the future to install them back. They must be numbered sequentially from front to rear of the engine. If not, number them yourself with a marker or brand (see picture). The main bearing cap usually has a molded arrow pointing towards the front of the engine (see picture). Loosen each cover bolt 1/4 turn one at a time until they can be tightened by hand.

5. Gently tap the caps with a soft-edged hammer, then pry them off the block. If necessary, use the bolts as levers to remove the covers. If the insert comes off with the cover, be careful not to drop it.

6. Carefully remove the crankshaft from the engine. Help is needed at this point, as the crankshaft is very heavy. Bearing shells with caps must be in the block, place the caps in their places in the block and hand-tighten the bolts.

Visitor comments