2. Remove the oil level dipstick.

3. Drain the oil, remove the oil filter (Chapter 1).

4. If the machine is equipped with a bottom oil level sensor, remove the retaining clip from the sensor and disconnect the contact wires from it.

5. Remove catalytic converter and tube assembly (chapter 4).

6. Remove the starter motor (chapter 5).

7. Remove the bottom dome cover (drive plates), if it exists in the model.

8. Turn off bolts of the oil pallet and remove it. If the pan does not budge, tap it with a rubber-edged leveling hammer.

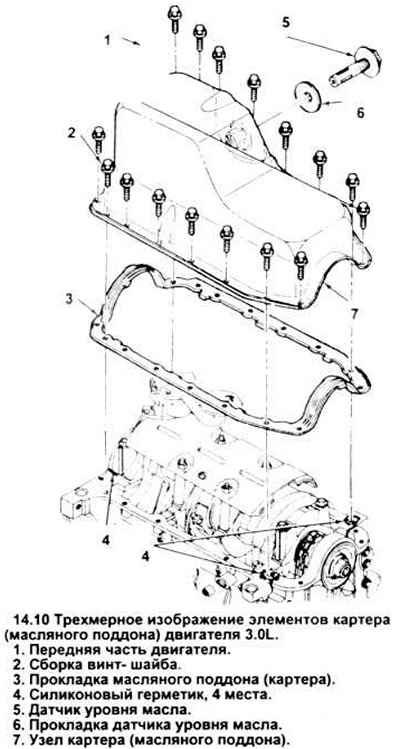

9. Remove the remains of the old gasket from the contact surfaces (see picture) and flush the oil pan (see picture).

10. Install a new gasket on the oil pan (see picture) using glue (Ford D7AZ - 19B508 - A or similar).

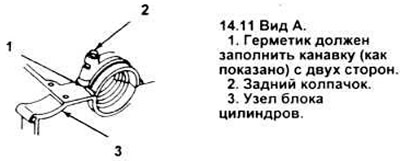

11. Apply a 1/6" thick coat of RTV Sealant (type Ford D6AZ - 19562 - A or similar) at the junction of the engine block and the cover of the main rear bearing, as well as the cover of the adjusting chain, in four places in total (see picture). Install end seals if necessary.

Note: Strictly follow the gasket manufacturer's instructions. Don't let the sealant dry before you install the pan.

12. Install the oil pan (crankcase) on the engine block and start the bolts: tighten them to the torque value specified in the specification.

13. Reassemble the remaining parts in the reverse order of disassembly.

14. Install a new oil filter, add oil, start the engine. Check for oil leaks.

Visitor comments