2. Remove valve levers and push rods (section 4).

Note: On engines with roller tappets, be sure to mark the front of each tappet before removing it (if it no longer has a ledge or notch), so that the rollers rotate in the same direction after installation. Also unscrew and remove the pusher guide retainer and pusher guides (see picture).

3. The pushers are removed from the holes in several ways. Special tools have been developed for gripping and extracting pushers (Ford T70L - 6500 - A and similar), manufactured by various companies and widely available (see picture), but not suitable in all cases.

4. On relatively new engines with a little carbon deposits, the pushrod can be removed with a small magnet or just with your fingers. A straightedge with a bent end can be used to pull out the tappets by passing it under the retainer ring at the end of the pusher.

Caution: Do not use pliers to remove pushrods. unless you are going to change them for new ones (along with distributor). Pliers can damage the polished hardened surfaces of the tappets, making them unusable. In engines with a lot of dirt and soot, move the tappets up and down, use a carburetor cleaning spray to remove the effect of dirt.

5. Clean them with solvent and dry thoroughly, then install them in order.

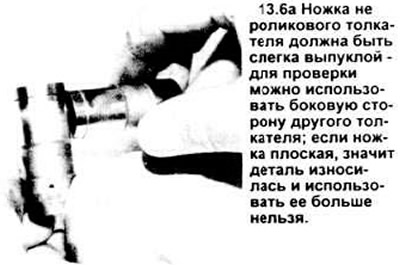

6. Check walls, rod seat and bottom of each pusher for scratches, nicks, heavy wear. On flat (not roller) pushers, the leg of each pusher (camshaft cam sliding surface) should be slightly convex, although it is difficult to see by eye.

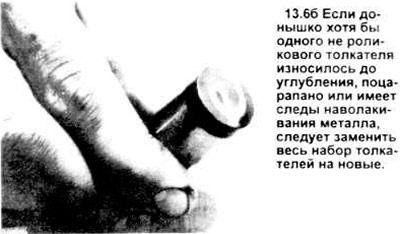

If the base of the pusher is concave (see picture), the tappets and camshaft should be replaced. If the sides are worn or damaged (which is unlikely), check the tappet holes in the engine block. If the rod seat is worn (see picture), check the ends of the rods. On roller-type pushers, check that the rollers rotate freely and that their surfaces are not worn or damaged.

7. When installing new pushers, the camshaft must also be changed. And vice versa.

Visitor comments