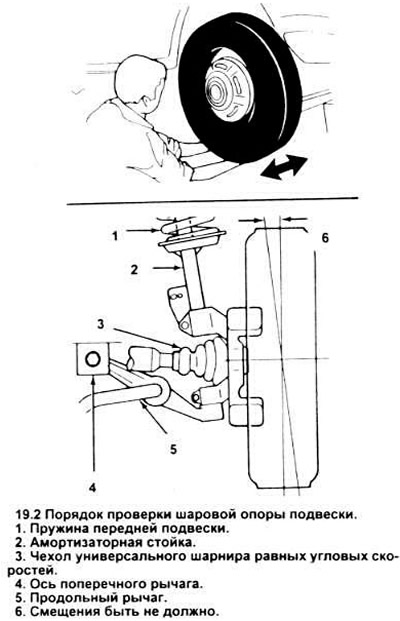

2. Wipe off any dirt from the lower end of the ball joint and control arm. Grab the bottom of the tire and slide the wheel out (see picture), to determine the play in the ball-and-lever assembly. If it is, the suspension ball joints should be replaced.

3. Grasp the wheel as shown in figure 19.3 and move it back and forth. Having found the play, check the suspension mounting and tightness of the ball pins of the steering rods. Tighten the loose suspension mount. If the tie rods are loose, the ball joints may be worn out (fingers) - check fastening of nuts. For more information on steering and suspension, as well as drawings, see chapter 10.

Front wheel bearing check

Note 1: Closed type front wheel bearing, lubrication and gasket installation are carried out in the factory. Maintenance and adjustment is not subject to. However, they can be checked for too much play. If the check shows the unsuitability of the outer bearing, then both of them should be replaced

Note 2: This procedure should also be done on rear wheel bearings on 1990 and later models.

4. Grab the wheel as shown in the illustration and rock it back and forth to find play. There should be no noticeable shift. Spin the wheel and listen to the noise in the bearings. If something is noticeable, see the bearing replacement procedure in chapter 10.

Checking the covers of the universal joint of equal angular velocities of the axial drive

5. If the rubber boots of the axle drive are damaged or worn, then the universal joint of constant angular velocity is threatened with serious damage.

6. Check 4 cases (2 on each axis) for cracks, holes, tears, worn rubber, and loose or non-functioning clamps. By pressing on the surface of the cover, you can find previously invisible cracks (see picture).

7. If you find damage or fraying, check the CV joint assembly itself (chapter 8) and replace the case with new ones.

Visitor comments