Note: if the CV joint is worn and needs to be overhauled (usually due to torn anthers), Read all instructions before starting repairs.

Preparation

1. Remove axle drive (section 8).

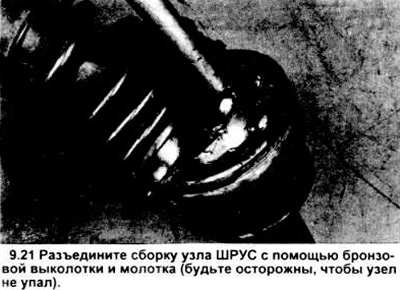

2. With the right axle drive removed on vehicles with a manual or 3-speed automatic transmission, install the connecting shaft in a vise with a wooden spacer. Disconnect the axle drive from the bonding roller by knocking it out through a bronze punch (see picture). Do not let the axle drive fall to the floor after it has come out.

3. Place the axle drive in a vise with a wooden spacer to avoid crushing the shaft.

Inner CV joint assembly and cover

Disassembly

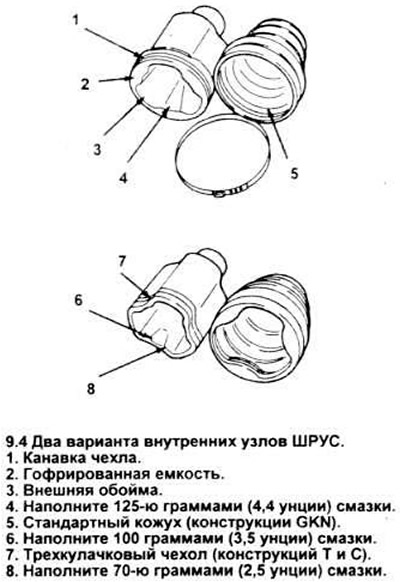

4. Note internal CV joints are of two types (see picture). Although they are similar in design, their parts are not interchangeable. The repair procedure is the same for both. Cut the boot seal retaining clips and slide the boot towards the center of the axle drive. Mark the tee body and axle drive so that they can be returned to their original position, then pull them off the hub.

5. Mark hub assembly and shaft. Remove the hub assembly from the axle by first removing the inner circlip and pulling the hub back to release the outer circlip. Remove the outer retaining ring, pull the assembly off the axle drive (see pictures).

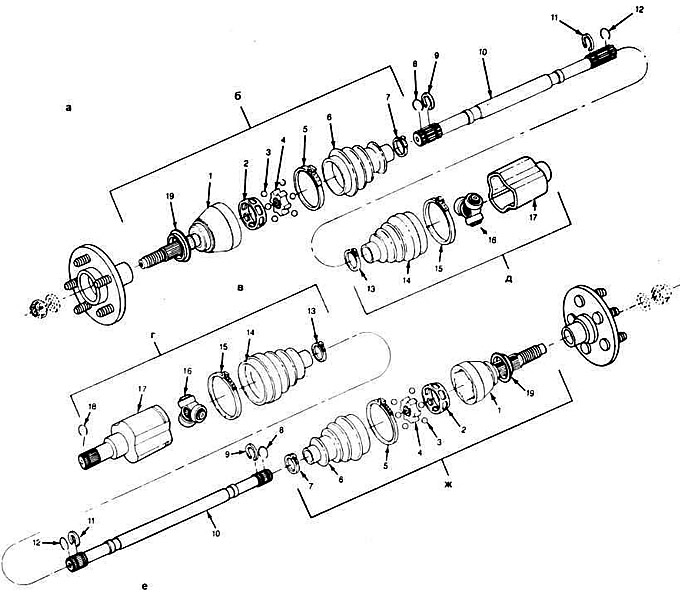

9.5, a. Three-dimensional representation of the elements of the axial drive.

A. axle shaft - disassembled view.

b. outer CV joint

V. left half shaft

d. inner CV joint

e. internal CV joint assembly.

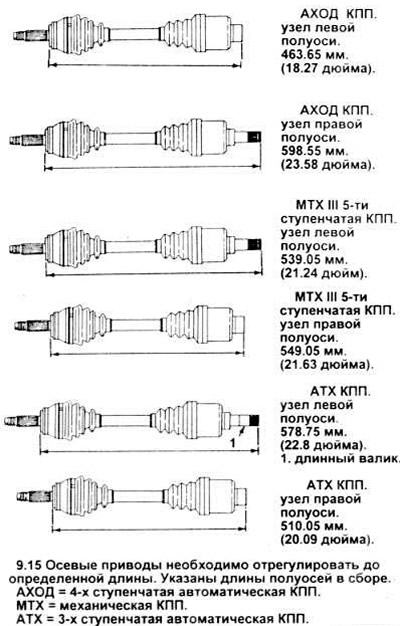

e. right axle shaft.

and. external CV joint.

Note: When replacing a boot, CV joint, intermediate shaft, or entire axle shaft assembly, familiarize yourself with the type of gearbox, its gear ratio, engine size, and determine the left or right side, the outer or inner end.

1. The outer race of the outer assembly and the shortened roller.

2. Clip for balls.

3. Balls (6 items).

4. Inner cage of the outer assembly.

5. Case clip (big).

6. Cover.

7. Case clip (small).

8. Spring ring.

9. Retaining ring.

10. Intermediate shaft.

11. Retaining ring.

12. Spring ring.

13. Case clip (small).

14. Cover.

15. Case clip (big).

16. Knot internal triple hinge.

17. Internal knot of an internal clip and the shortened roller.

18. Spring ring.

19. Anther.

6. After wrapping the hub bearings with tape or a rag, lock them during assembly and disassembly.

7. Remove the hub assembly from the axle.

8. Pull the boot off the axle.

Examination

9. Clean the grease from the hub and its body. Carefully disassemble the hub assembly piece by piece, removing one at a time, flush the needle bearings with solvent. Check the rollers, hub cross, bearings, and housing for scratches, pitting, and other signs of excessive wear that may warrant replacement of the CV joint internal assembly.

Assembly

10. Apply a coat of special grease to the inside surfaces of the bearings to hold them in place when assembling the hub assembly. Stuff the case with grease equal to half the capacity of the new case, and leave the rest in the case.

11. Tape the splines of the axle drive to avoid damaging the boot, then put the boot on the axle (see picture).

12. Install the hub bearing so that the chamfer is opposite the retaining ring (see picture).

13. Install a new circlip on the end of the shaft, slide the hub bearing against the circlip and install the retaining ring in the groove.

14. Install the triple pivot housing.

15. Insert the cover into the body and the sealing grooves of the axle, then adjust the length of the axle to normal (see picture).

16. After adjusting the shaft length, equalize the pressure in the boot by inserting a screwdriver between the boot and the housing (see picture). Do not damage the case with the tool.

17. Install shroud clips. Special pliers are used to tighten the clamps.

Caution: Use only low profile clips on internal CV joints.

18. Connect the axle drive to the connecting shaft (only the right side on all manual and 3-speed automatic transmissions).

19. Install the axle drive (or drive unit with tie shaft) as described in section 8. Don't forget to install a new circlip on the inner short axle.

External CV joint assembly and cover

Disassembly

20. Follow paragraphs 2 and 3 in this section.

21. Cut the retaining clips of the boot and remove it from the outer clip. By installing a bronze drift in the inner cage, release the CV joint assembly from the axis (see picture). Significant force will be required, since the inner race will have to overcome the resistance of the axial shaft. Don't let the CV joint fall.

22. Place the outer assembly in a vise through the wood shims.

23. Press the inner race down just enough to remove the ball bearing. If it is difficult to tilt, then knock out the inner clip with a hammer through a bronze drift (see picture).

24. Pull the balls out of the separator one by one with a flat screwdriver (with rounded end) or wooden tool (see picture).

25. After removing all the balls from the separator and turning the inner cage separator 90 degrees, align the separator openings with the planes of the outer cage and pull the assembly out of the outer cage (see picture).

26. Remove the inner race from the separator by turning it 90 degrees in the separator, aligning its planes with the openings in the separator and turning the inner race from the separator (see picture).

Examination

27. Clean elements with solvent to remove all traces of grease. Check cage and cages for pitting, scratches, cracks, and other signs of wear and damage. Shiny, polished spots are normal and will not affect the performance of the CV joint (see pictures).

Assembly

28. Install the inner race into the cage in sequence. the opposite of that given in paragraph 25.

29. Install separator assembly with inner race in sequence. reverse disassembly (paragraph 25). The beveled edge of the splined part of the inner race must "look" outside after installation in the outer cage (see picture).

30. Press the balls into the windows (openings) separator (see picture).

31. Pack the CV joint assembly with grease through the internal slotted hole. Push the grease into the bearing - by inserting a wooden pin into the splined hole, push it to the bottom of the assembly. Repeat the procedure until the bearing is completely filled with grease (see picture).

32. Put on a cover on an axial shaft. as stated in paragraph 11. Apply some grease to the inside of the axle boot.

33.Install a new retaining ring and place it in the groove of the axial shaft.

34. Install a new circlip on the end of the axle shaft.

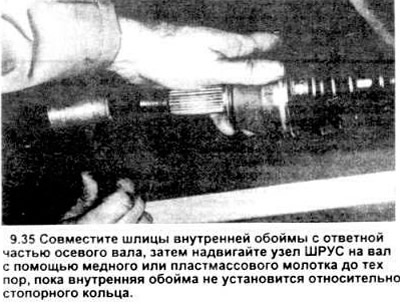

35. Place the CV joint assembly on the axial shaft, aligning the splines. Using a hammer with a copper or plastic cushion, slide the CV joint assembly onto the axial shaft until it stops against the retaining ring (see picture).

36. Adjust the length of the axle drive and put on the cover. See paragraphs 16-17.

37. Assemble the Axle Drive Assembly with Link Shaft (only the right side and only in 3-speed automatic transmission).

38. Install the axle drive as instructed in section 8.

Visitor comments